Advanced Servo Motors ...

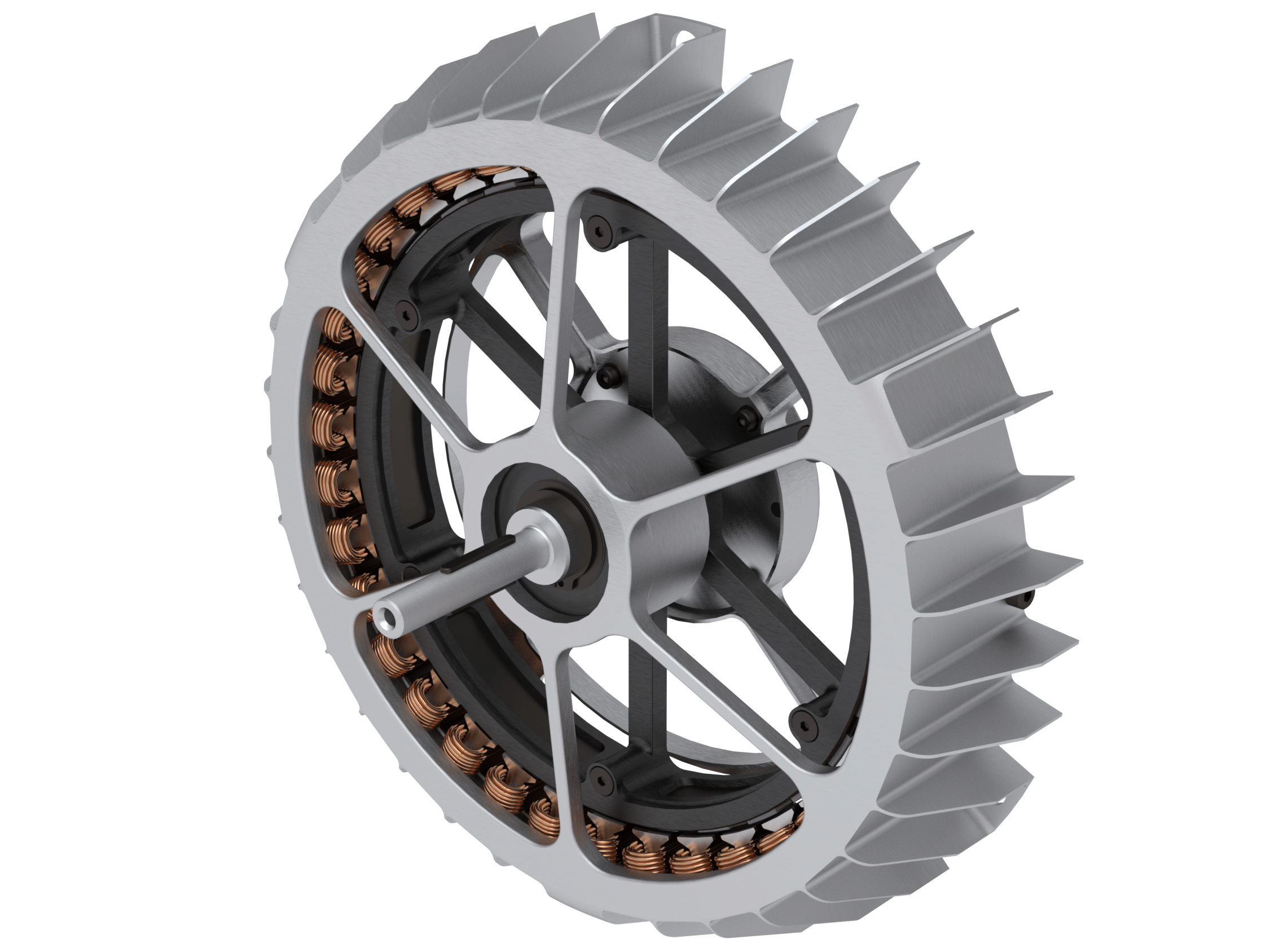

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

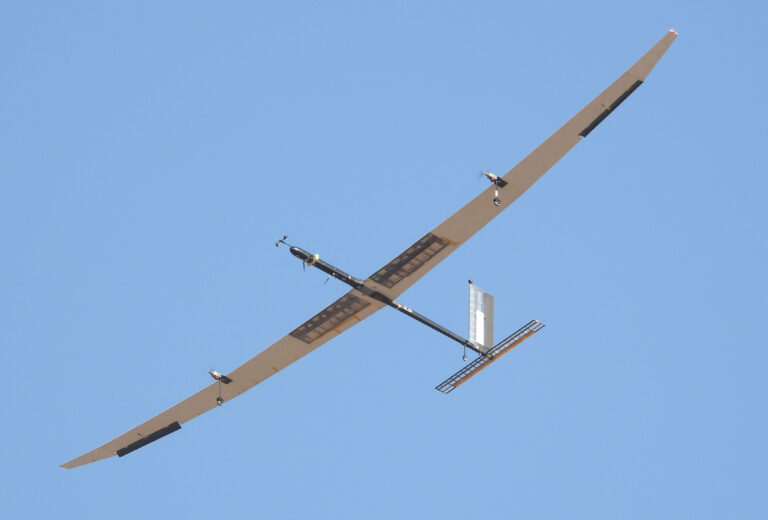

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

NewsOctober 2023

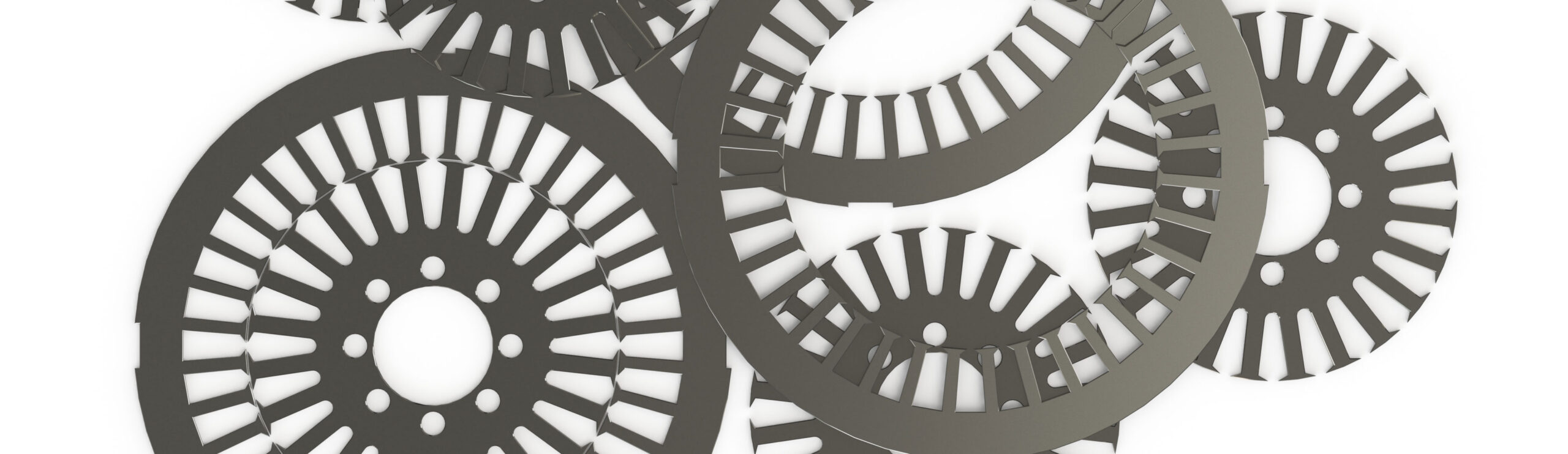

Why use Cobalt Steel for Motor Lamination Designs?

Cobalt steel, also known as cobalt-iron alloy or cobalt laminations, is used in the construction of motor laminations for several important reasons:

- High Saturation Magnetization: Cobalt steel has a high saturation magnetization, which means it can hold a strong magnetic field. This property is crucial for the efficient operation of electric motors, as it allows for higher magnetic flux density and, consequently, higher energy efficiency

- Low Core Loss: Cobalt steel has low core losses, also known as hysteresis losses. These losses occur due to the repeated magnetization and demagnetization of the material during each cycle of the alternating current passing through the motor. Lower core losses mean higher efficiency, as less energy is wasted as heat

- High Curie Temperature: The Curie temperature is the temperature at which a material loses its magnetic properties. Cobalt steel has a high Curie temperature, allowing it to maintain its magnetic properties at high temperatures. This is important because electric motors often generate heat during operation, and the material needs to retain its magnetic properties under these conditions for optimal performance

- High Mechanical Strength: Cobalt steel has good mechanical strength, making it durable and resistant to mechanical stress. This property is essential for motor laminations, as they need to withstand the mechanical forces and vibrations experienced during motor operation

- Corrosion Resistance: Cobalt steel is resistant to corrosion, which ensures the longevity of the motor laminations. Motors are often exposed to various environmental conditions, and using a corrosion-resistant material helps prevent damage and maintains the motor's performance over time

- Dimensional Stability: Cobalt steel maintains its dimensional stability even under the influence of strong magnetic fields. This property ensures that the motor laminations retain their shape and do not deform, which is crucial for the precise assembly of electric motors

In summary, the unique combination of high saturation magnetization, low core losses, high Curie temperature, mechanical strength, corrosion resistance, and dimensional stability makes cobalt steel an ideal choice for motor laminations, enabling efficient and reliable operation of electric motors in various applications.

Call our application team to discuss your specific motor requirements ...

Want to find out more?

Get in touch