Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

Precision Assembler - Electric Motor Wiring - Motor Development Technician

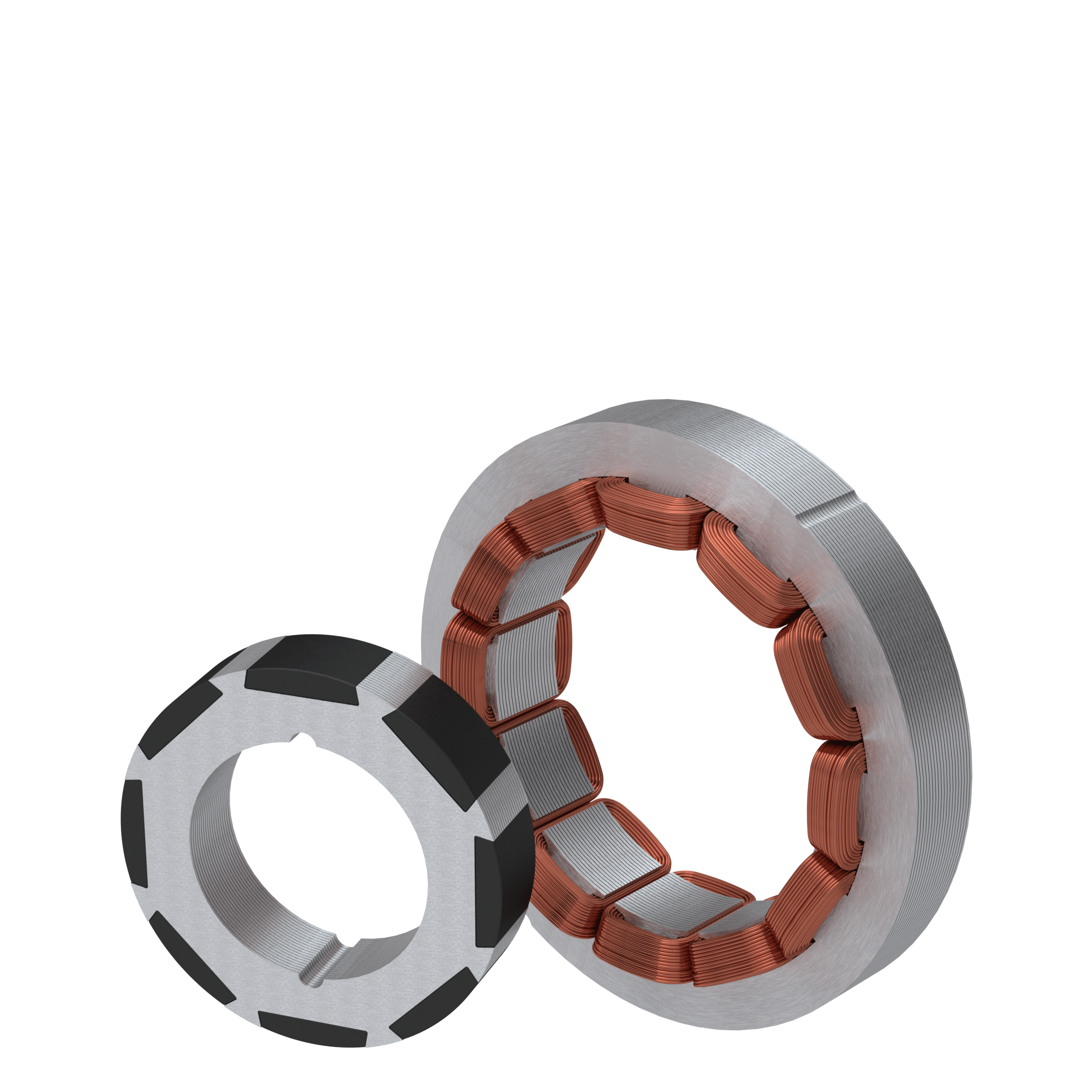

PMW Dynamics design and manufacture servo motors in many different configurations. Our designs vary from pancake, printed armature, axial flux brushed motors to advanced, bespoke, brushless motor solutions. All motor designs are originated on-site by our expect motor development specialist

We now seek to expand our production team with a new role responsible for the manufacture of prototype and low batch quantity production brushless motors

The role will involve all aspects of motor assembly including bonding high power, rare-earth magnets to rotor assemblies, insulation and hand/machine winding and lacing stator assemblies and post assembly potting and/or impregnation

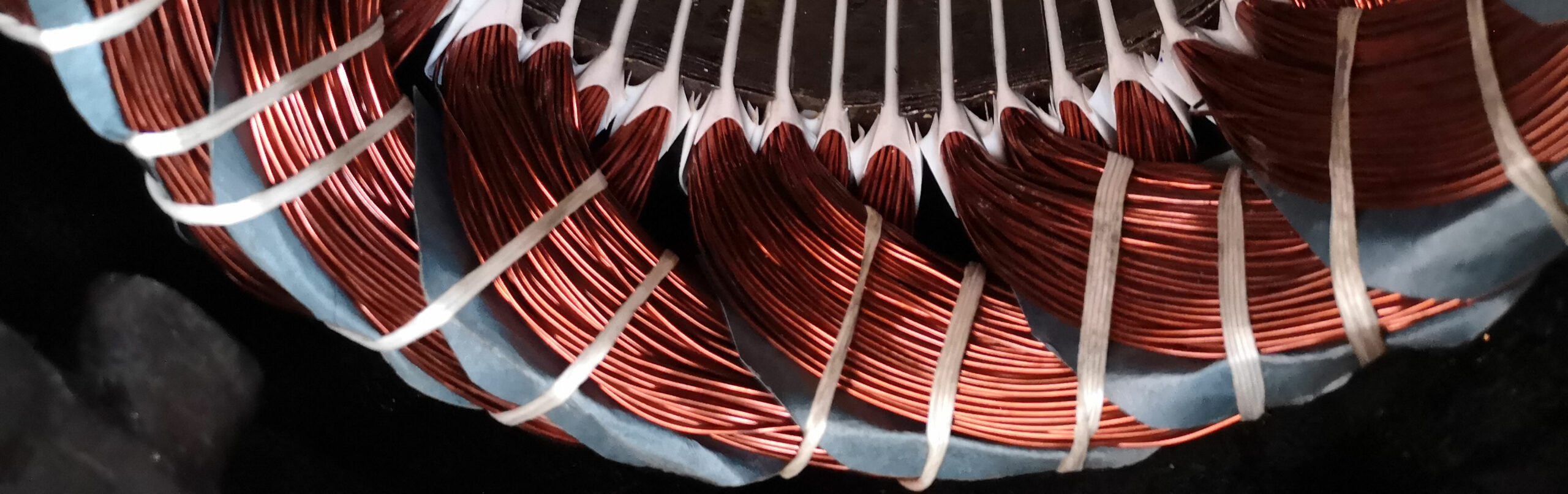

Winding a motor stator involves winding copper wire around motor “teeth” in a precise pattern paying particular attention to the number of turns per tooth and the layering of the turns to achieve maximum fill. Once wound and terminated, the coils are secured in-place with manual lacing

Ideally, you will have experience of motor hand winding but, if not, you are likely to be from a wiring loom manufacturing or chassis prototype wiring background which highly transferrable skills to undertake motor winding

Key requirements include …

- Motor Winding or Manual Wiring Experience

- Advanced Manual Soldering, Wire Termination and Crimping Skills

- Keen Eye-Sight and High Manual Dexterity

- Highly Logical & Methodical Work Patterns

- Keen Attention to Detail

- Ability to Understand and Follow Detailed Wiring Diagrams

Stator winding can vary from a few hours to many days depending upon the size and complexity of the motor meaning that careful and accurate recording of the winding progress, especially when spread over multiple days, is essential

PMW offer full on-the-job training to support skills development