Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

NewsAugust 2023

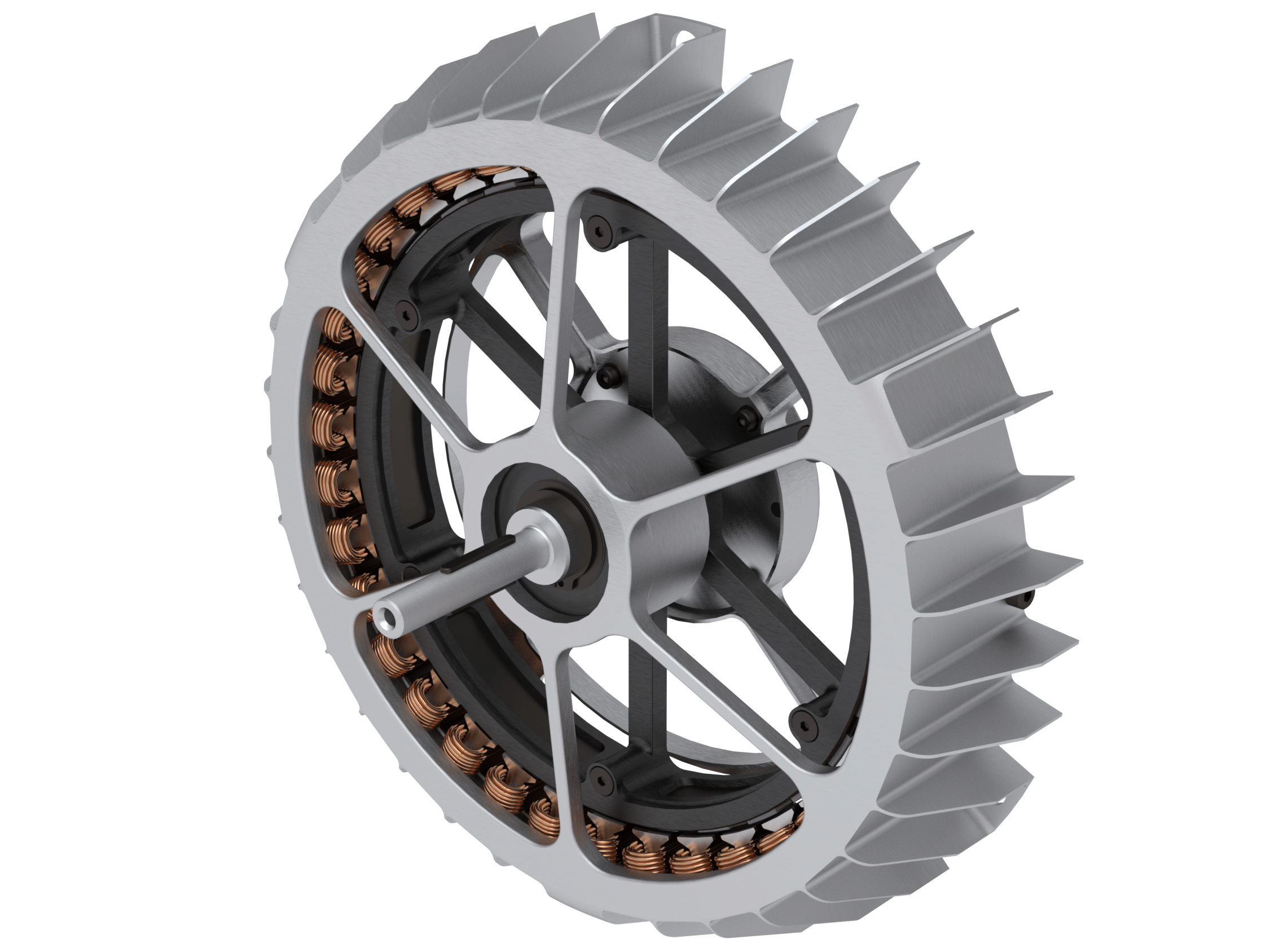

HALE UAV Propulsion Motor

Aerospace is experiencing increasing demand for high performance electric motors designed for optimal efficiency, minimal weight and long term reliability

Because of the industry’s extreme conditions of use and the complexity of system specifications, the phase-gated development that PMW offers its clients is perfectly suited to the level of optimisation required in the design process and through to manufacture of both motors and drives

Challenges

- Super Light Weight

- Highly Efficient

- Extreme Durability

- High Altitude Operation

Results

- Elaborate Materials & Critical Design

- Fully Optimised Electro-Magnetic Modelling

- Robust Design & Detailed Material Selection

- Comprehensive Environmental Analysis

PMW developed a brushless DC electric motor and drive (motor controller) for an all electric aircraft intended to say aloft for as long as a year at a time. It was the product of a challenge laid down by the aircraft’s designers Prismatic Ltd for its PHASA-35 high altitude, long endurance unmanned aerial vehicle (HALE UAV)

With twin bespoke electric motors directly driving high altitude propellers, the craft has arrays of solar panels to provide the power by day and recharge its batteries for flying at night

The cutting edge motor, drive and commutation system was required not to overheat at take off or during the fast climb necessary to reach its 65,000 feet cruising altitude in the limited time allowed

To do this, PMW’s design team quickly gained a precise understanding of the thermal performance required for the motor at all altitudes. The near space environment meant taking into consideration ambient temperatures of -80°C and a very low air pressure of 5.6 kPa

This required a detailed understanding of the three-dimensional heat dissipation from the motor and adjacent components, while ensuring every motor, drive and commutation component was both mechanically and electrically rated for all these conditions.

The phase-gated project included electromagnetic modelling, mechanical design, finite element analysis, component sourcing and procurement, and selection of specialist subcontractors to work with the extreme materials and precision required, followed by manufacture, assembly and test at both ambient and low temperatures

Contact our application team for assistance with your next challenging motor project ...

Have a similar challenge?

Get in touch