Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

NewsAugust 2023

Turntable for CMM

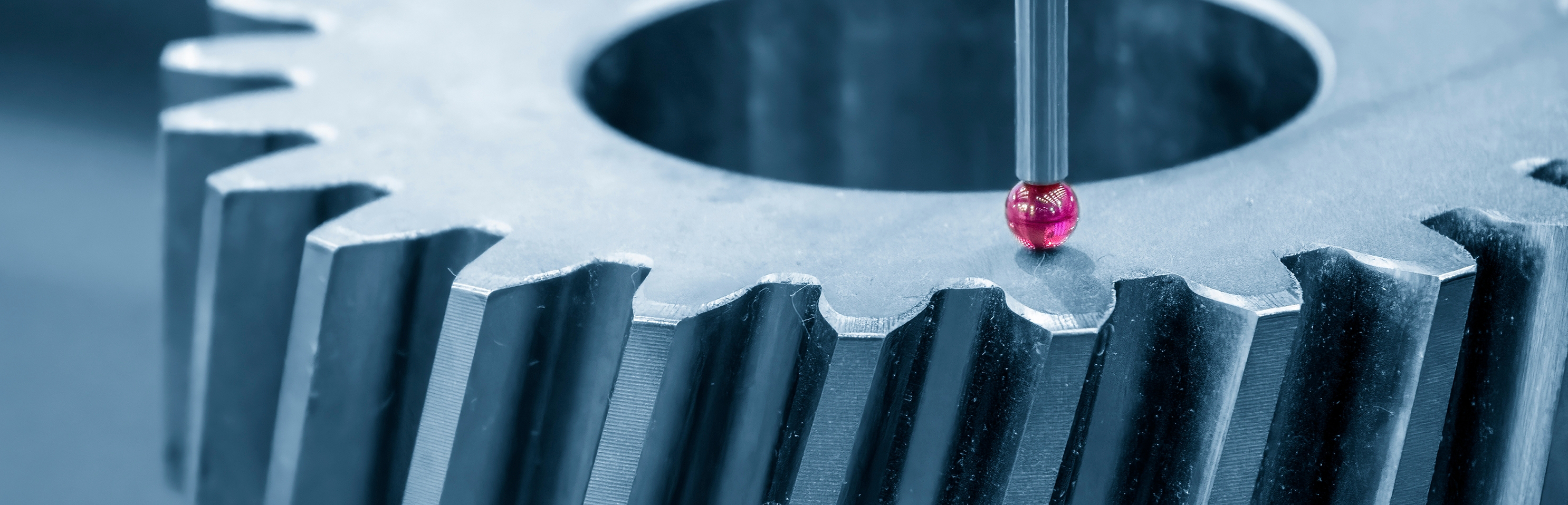

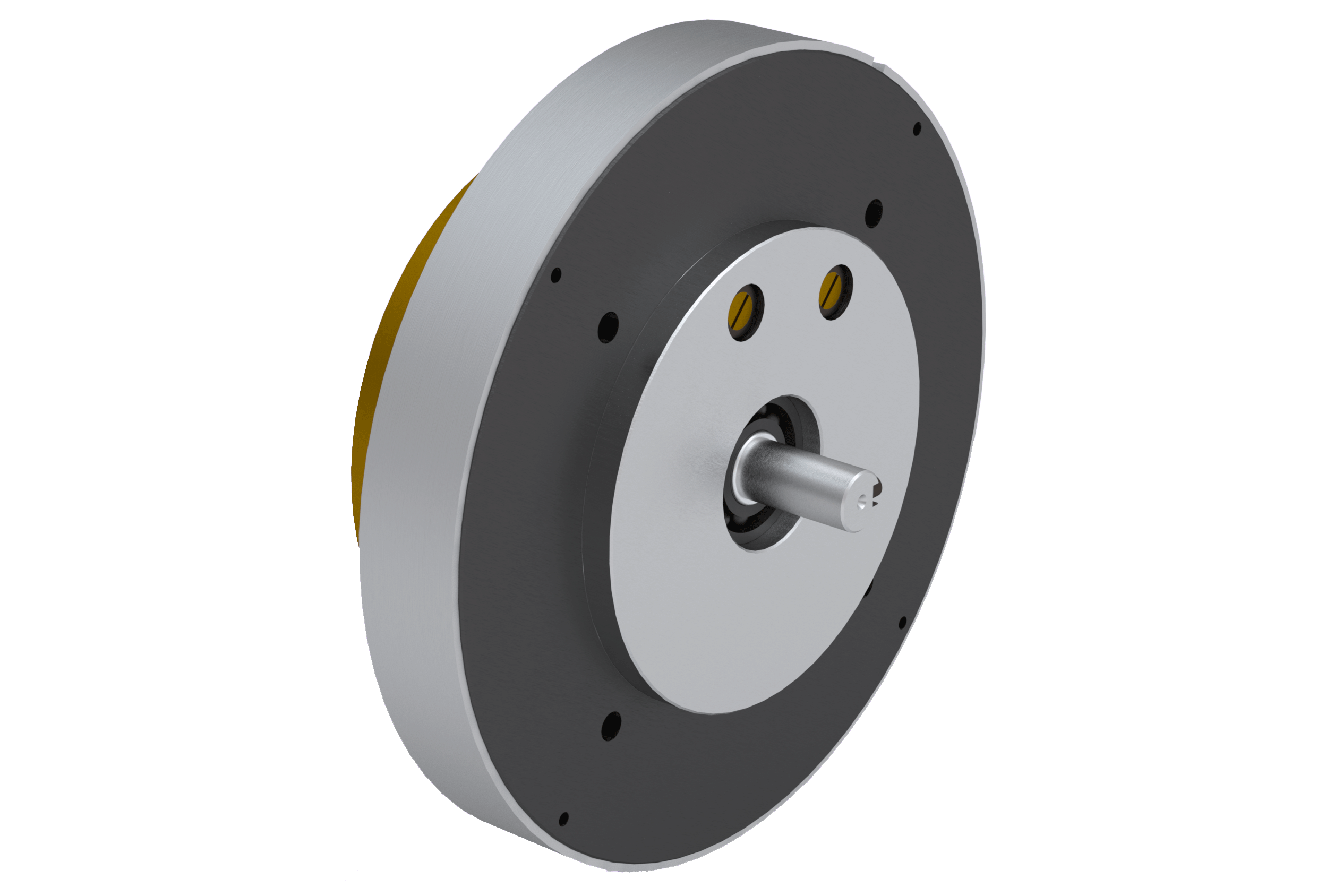

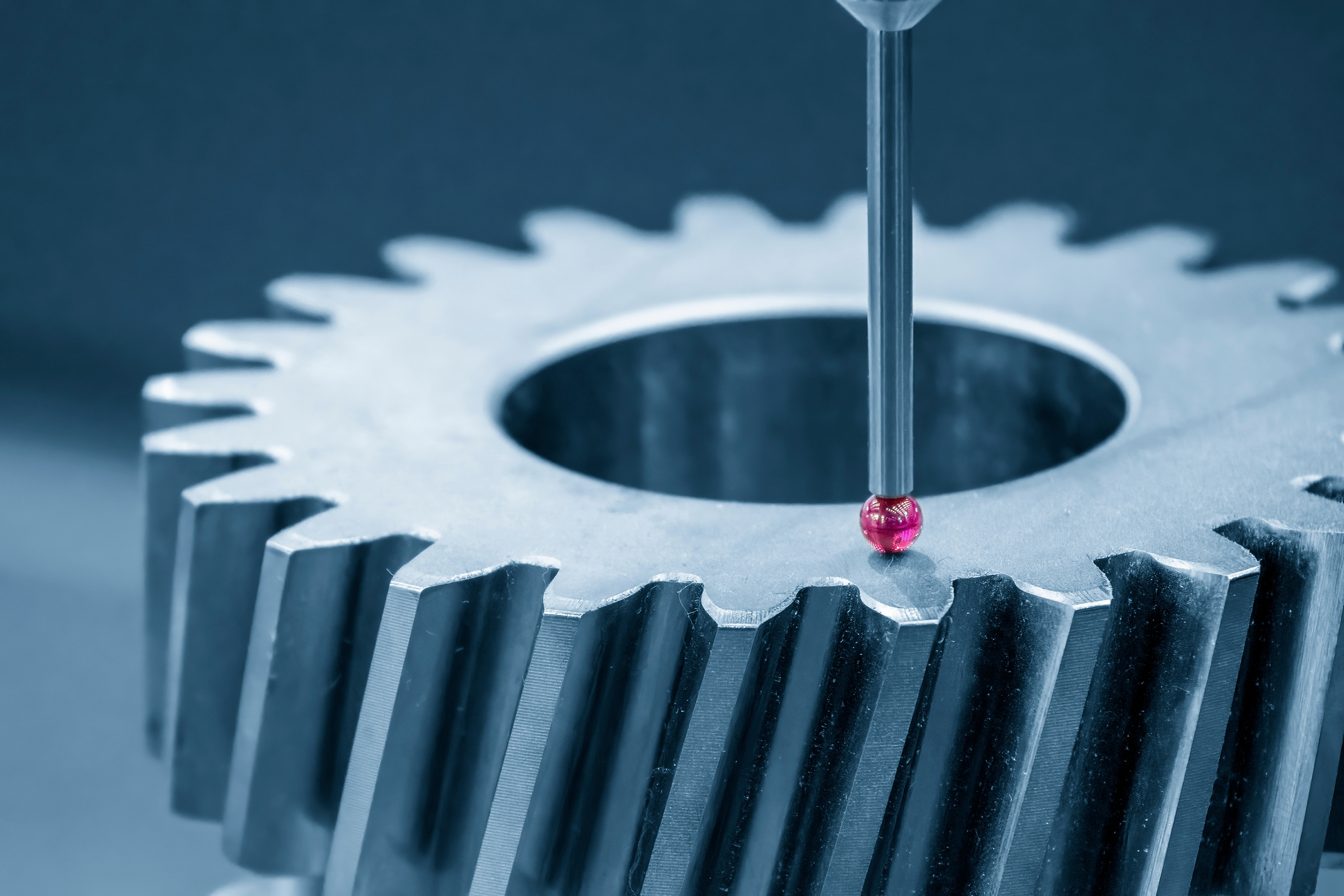

A higher powered GN9T motor is used in the drive train to rotate the sample turntable for coordinate measuring machine. Typical samples for measurement are aerospace turbine blades.

The requirement was for a very low profile servo motor with internal tachometer for speed feedback. The PMW GN9T brushed pancake motor with tacho feedback was chosen

Challenges

- Challenging Space Envelope

- Precise Velocity Control

- Accurate Velocity Measurement

Results

- Ultra Flat Printed Armature Motor

- Zero Iron Zero Cogging Design

- Integrated Tachogenerator

The overall height of the motor is sufficiently low to fit in the base plate of the turntable. Secondly, the GN9T motor uses an iron-free armature for zero cogging and no torque ripple under load, so that the motion is extremely smooth, ensuring angular precision of the workpiece

The motor is coupled to a zero-backlash strainwave gearbox, for precision angular motion. As there is a high ratio reduction gearbox between motor and turntable, even the slightest ripple in the torque would be amplified. This is eliminated with the GN9T motor.

Contact our application team for assistance with your next challenging motor project ...

Have a similar challenge?

Get in touch