NewsAugust 2023

Warehouse Robot

Robotics applications generally require powerful motors, but the limited space often available in mobile units can mean there is a need to combine high power with a very low profile. This is an ideal application for PMW’s external rotor motors, which produce high torque smoothly over a wide range of speeds from a very compact shape

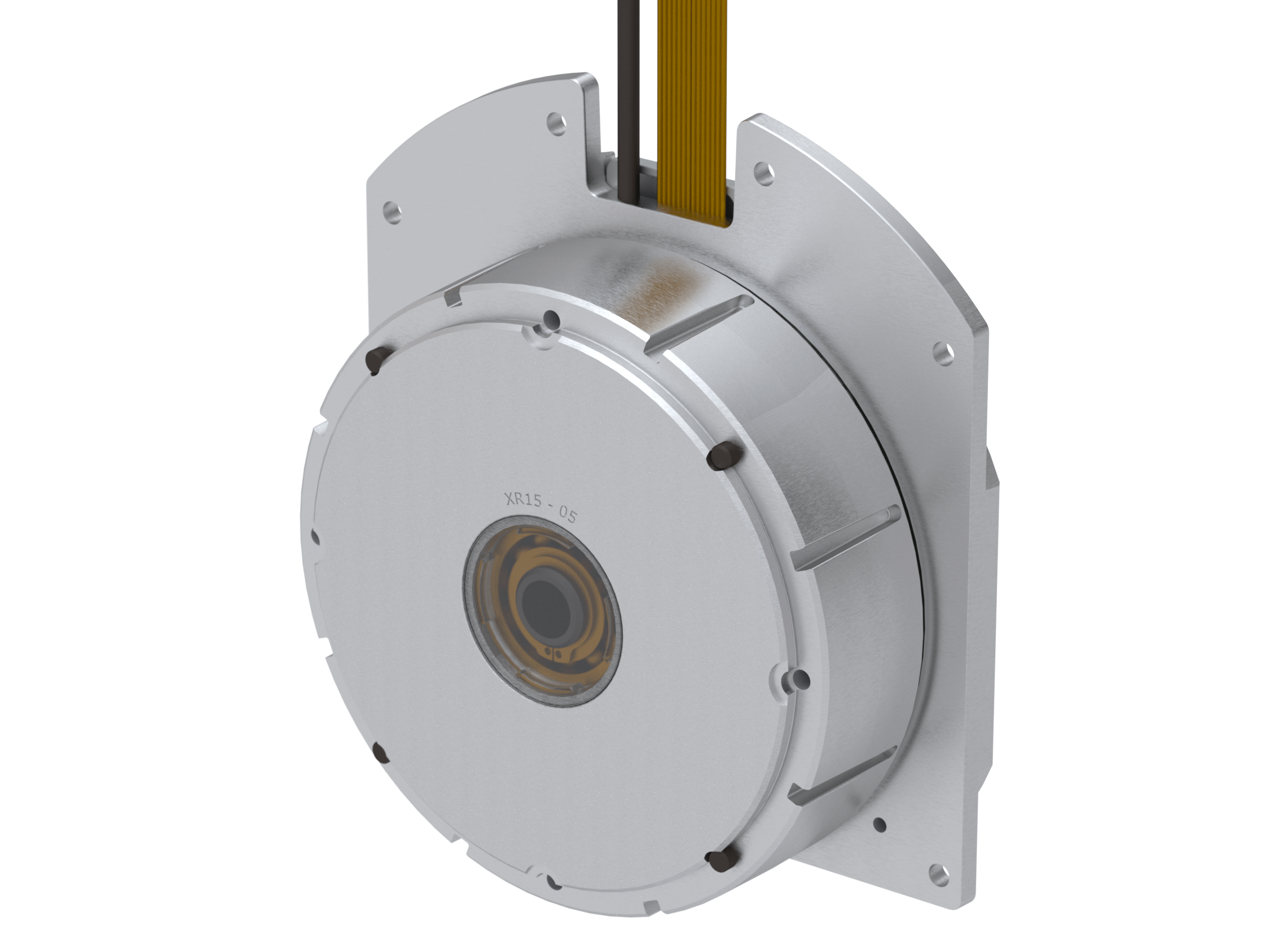

Applications range from in-wheel motors for AGVs and other specialist vehicles through to innovative warehouse storage and retrieval systems where our XR-15 motor works as a shuttle drive.

Challenges

- Ultra Compact

- High Torque

- Low Voltage

- Long Life

Results

- Pancake Outer Rotor Motor Design

- 8Nm Continuous 16Nm Peak

- 48VDC

- 20,000+ Operating Life

One of the key components for a new robot developed for a novel warehouse storage and retrieval system was its motor. As no commercially available motor fitted the company’s demanding specifications, PMW was asked to design and develop a compact but powerful model that could move the robots horizontally as well as raise and lower their loads.

The type of motor chosen was a permanent magnet brushless motor with an external rotor. Having its high strength neodymium magnets positioned on the externally running rotor gives it the fundamental advantage that the torque is generated at maximum radius, enabling it to produce high torque smoothly and over a wide range of speeds

Precise individual control of the robots was required, with positional feedback from the robot to the control system

During development, PMW precisely modelled the motor within the customer’s specification constraints, in order to optimise efficiency and unit cost. Electromagnetic modelling of the motor was carried out over a number of iterations, with the thermal studies based on the different duty cycle models and updated after customer reviews

The short axial length of the motor was crucial, since if it was as little as 2 mm longer it would have led to a substantial increase in the overall warehouse area

Contact our application team for assistance with your next challenging motor project ...

Have a similar challenge?

Get in touch