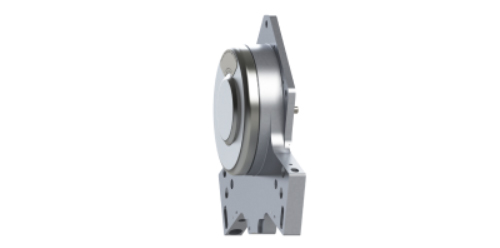

PMW worked closely with us on the design of the motor, which meets all the required torque, speed and thermal requirements. The quality of manufacture of the motors is also excellent, and they have performed faultlessly during testing

Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

Industry

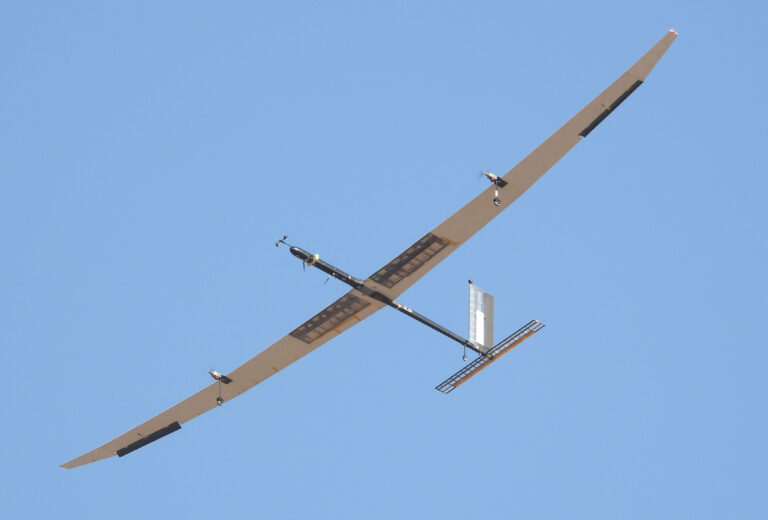

Automotive

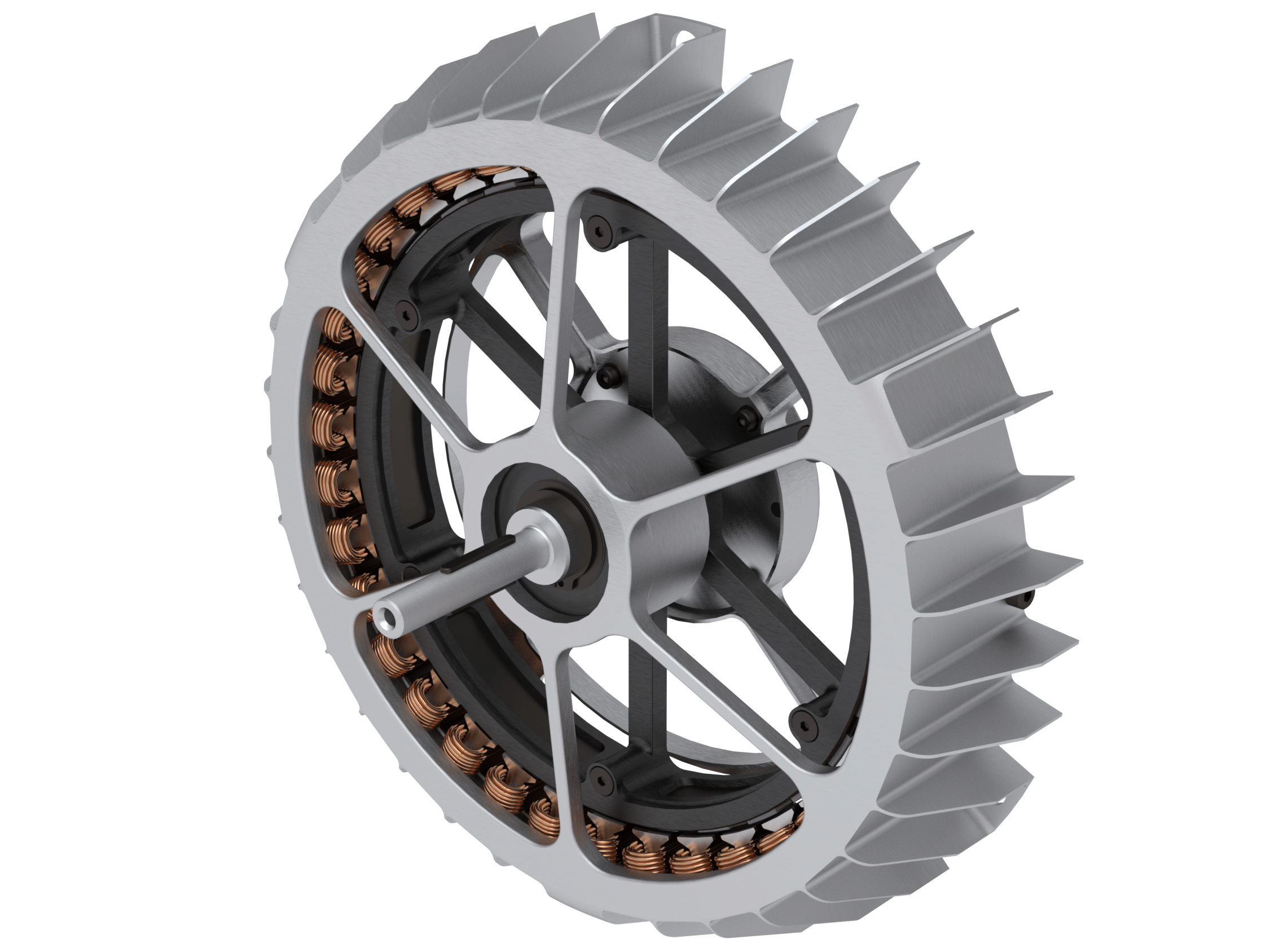

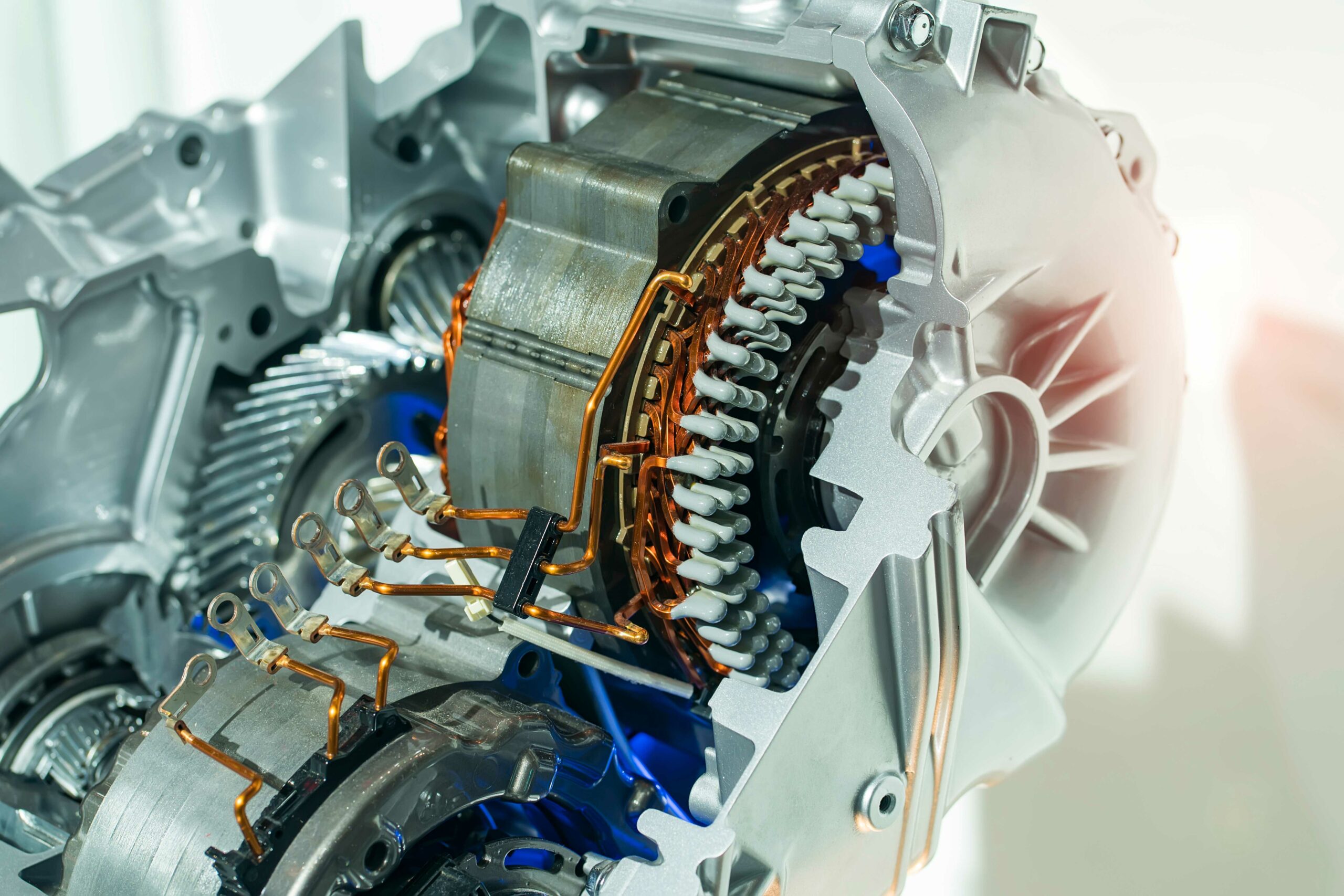

Powerful but lightweight electric motors are seeing an increasing demand in the automotive industry. Extremely high torque in-wheel electric motors from PMW are helping to meet the growing requirement for powerful motors in electric and hybrid vehicles

In addition, PMW’s brushless DC electric motors are powering hydraulic and air compressor pumps and simulation robots in vehicle design and test applications. They are also being used in electric power-assisted steering systems.

Get your custom designed motor

Get in touch