Advanced Servo Motors ...

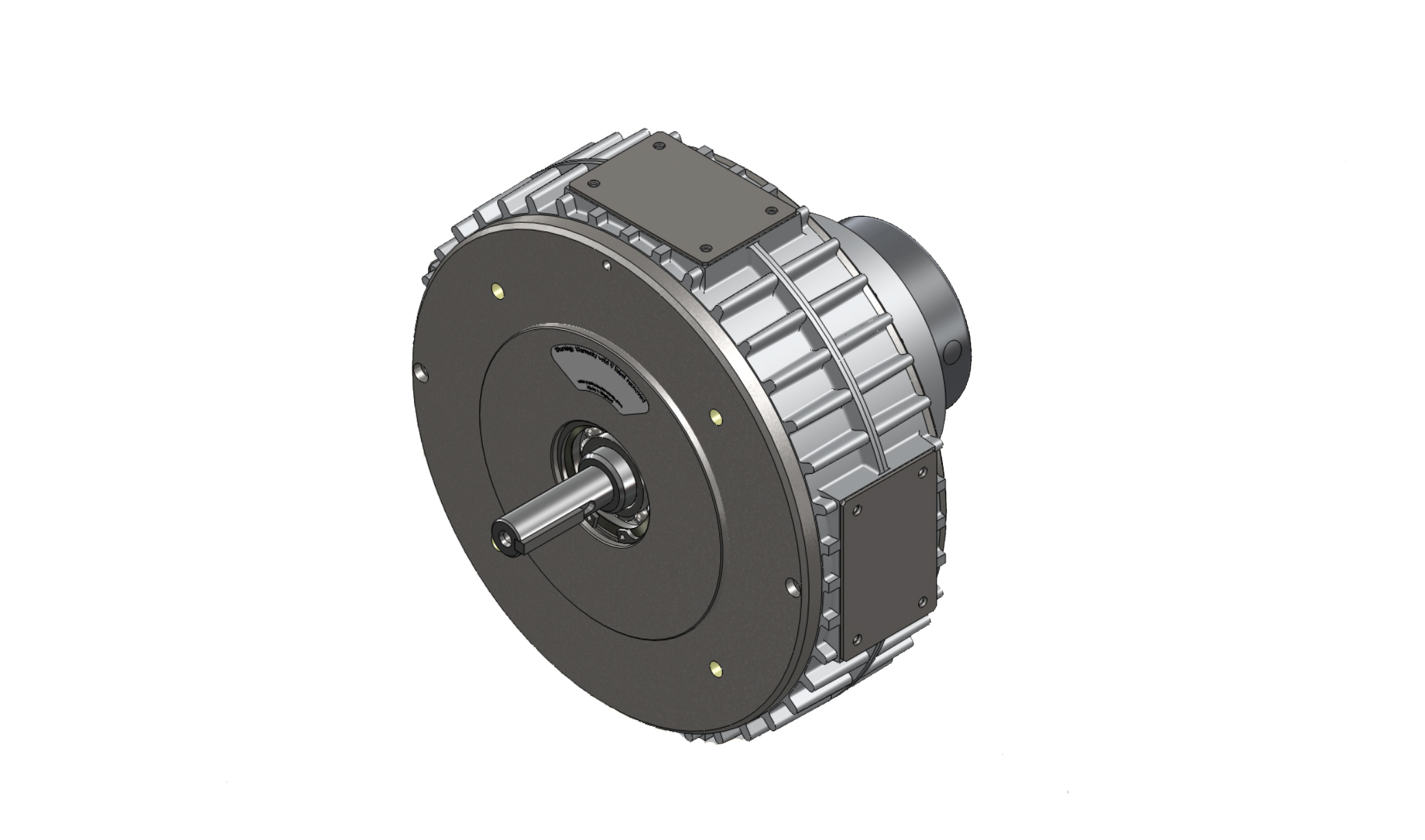

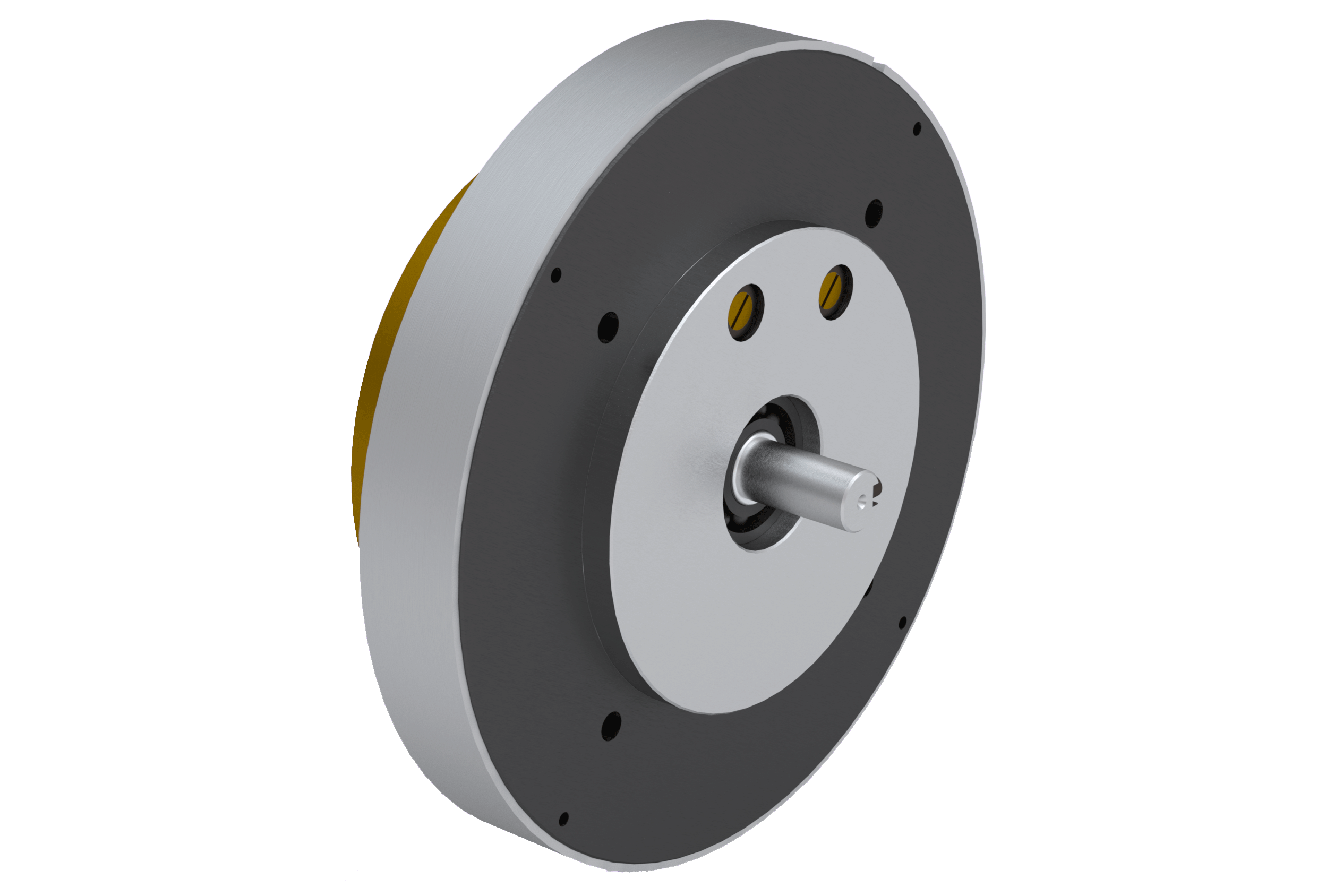

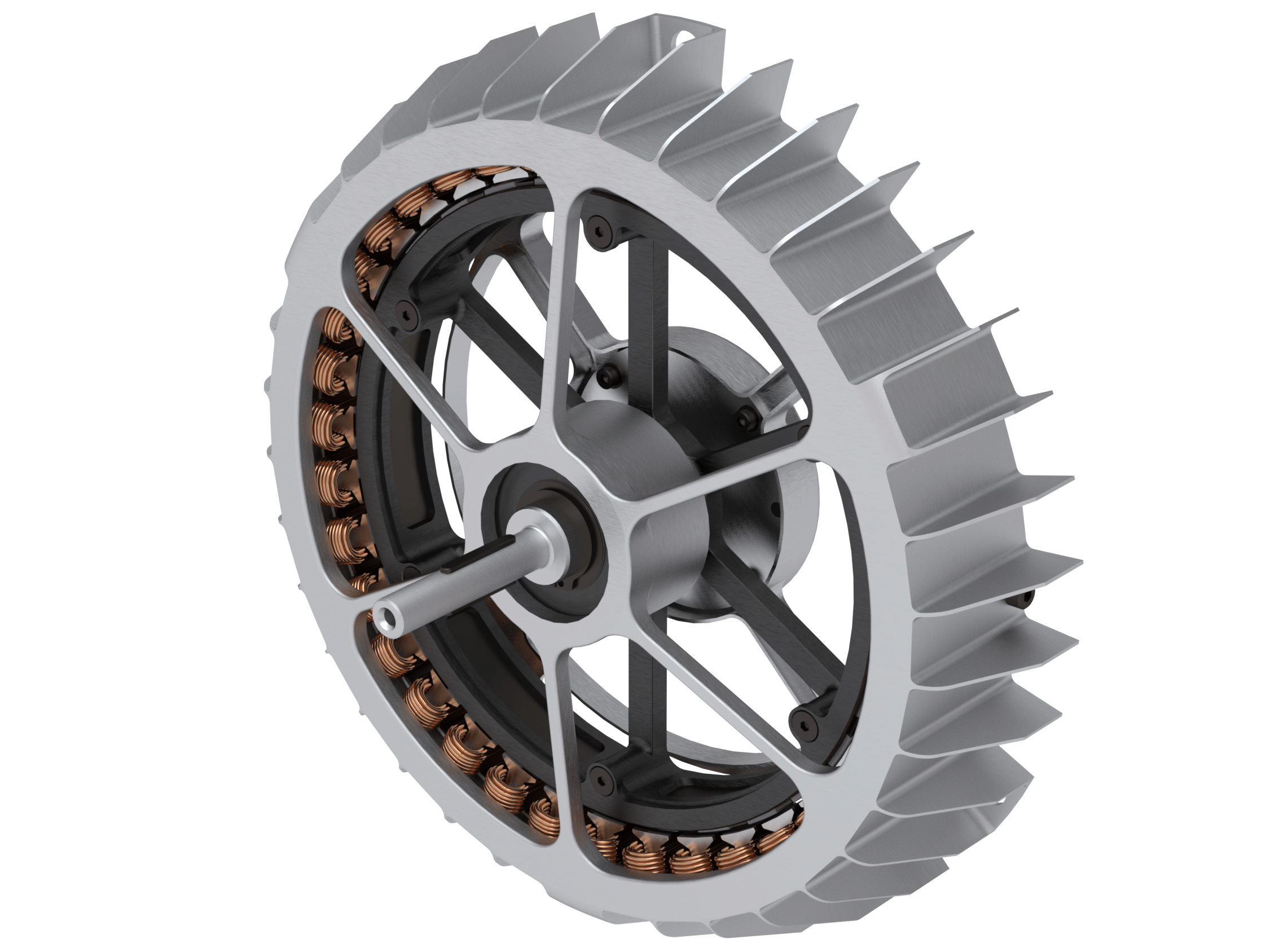

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

Industry

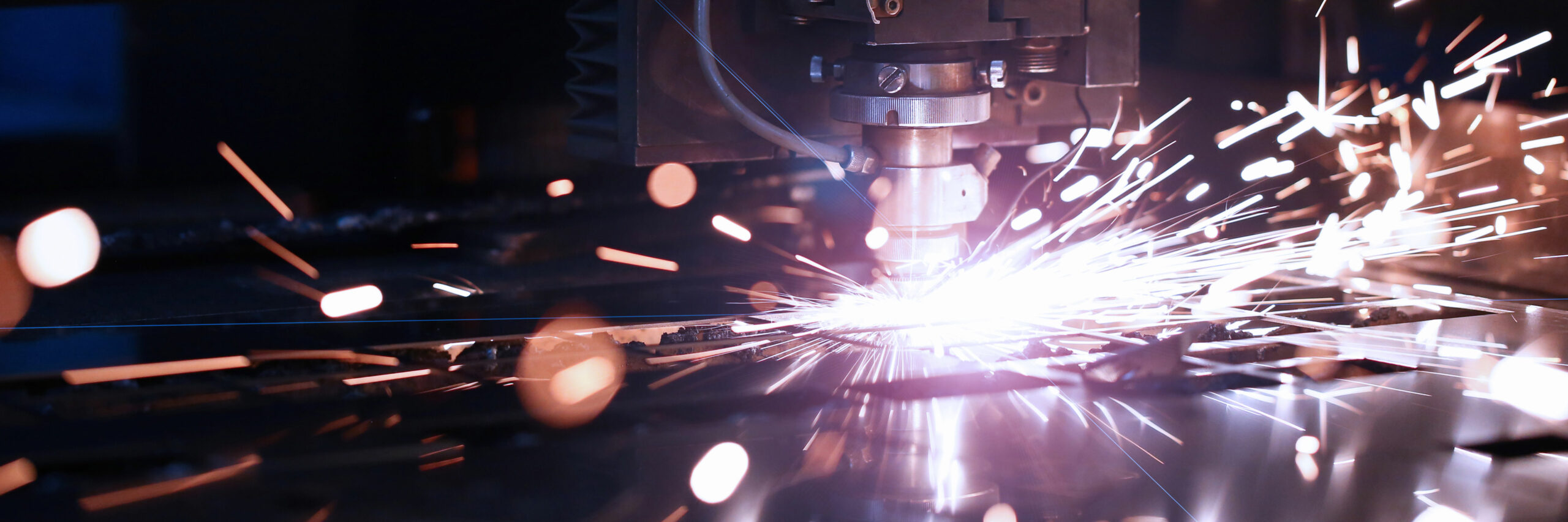

Industrial ...

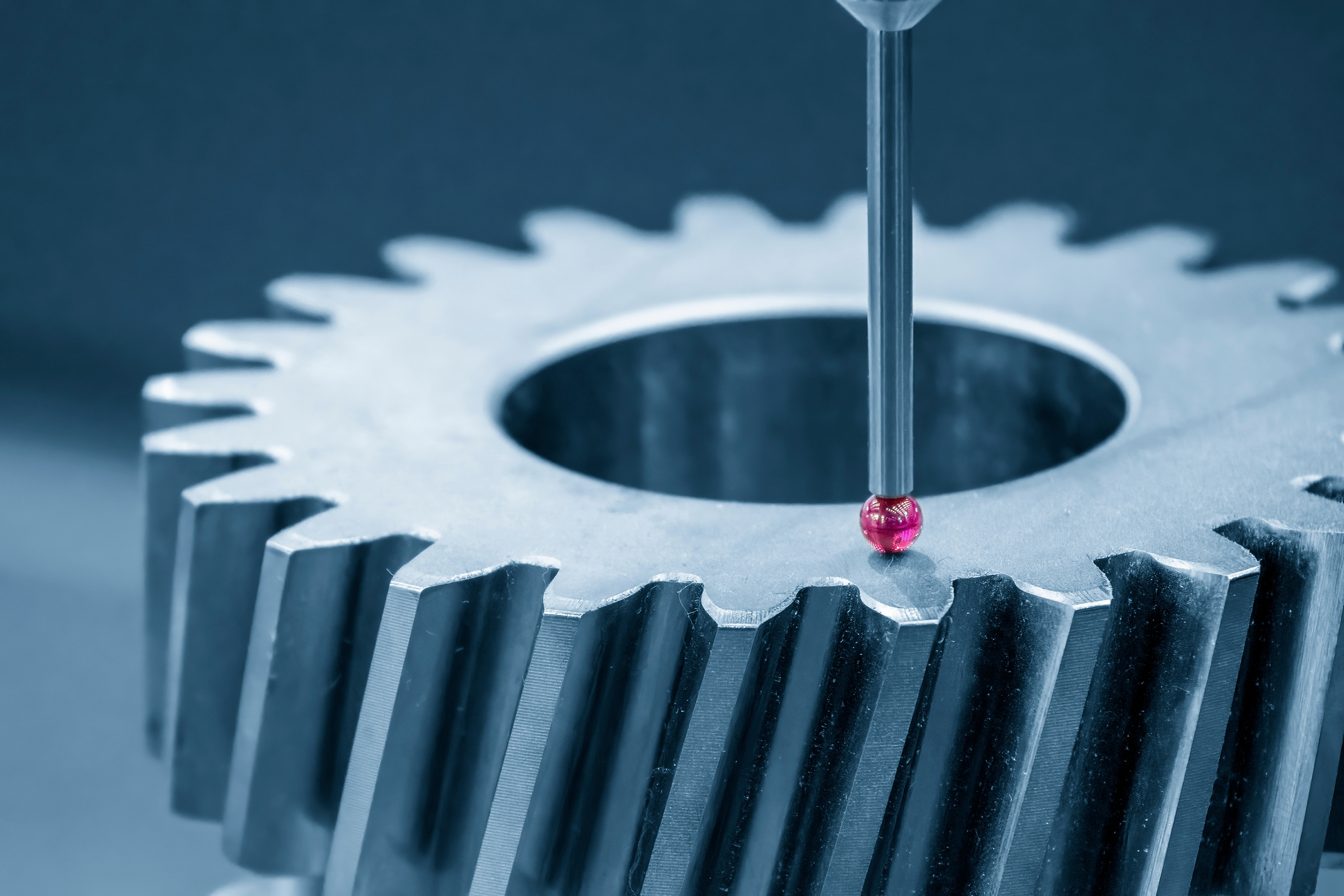

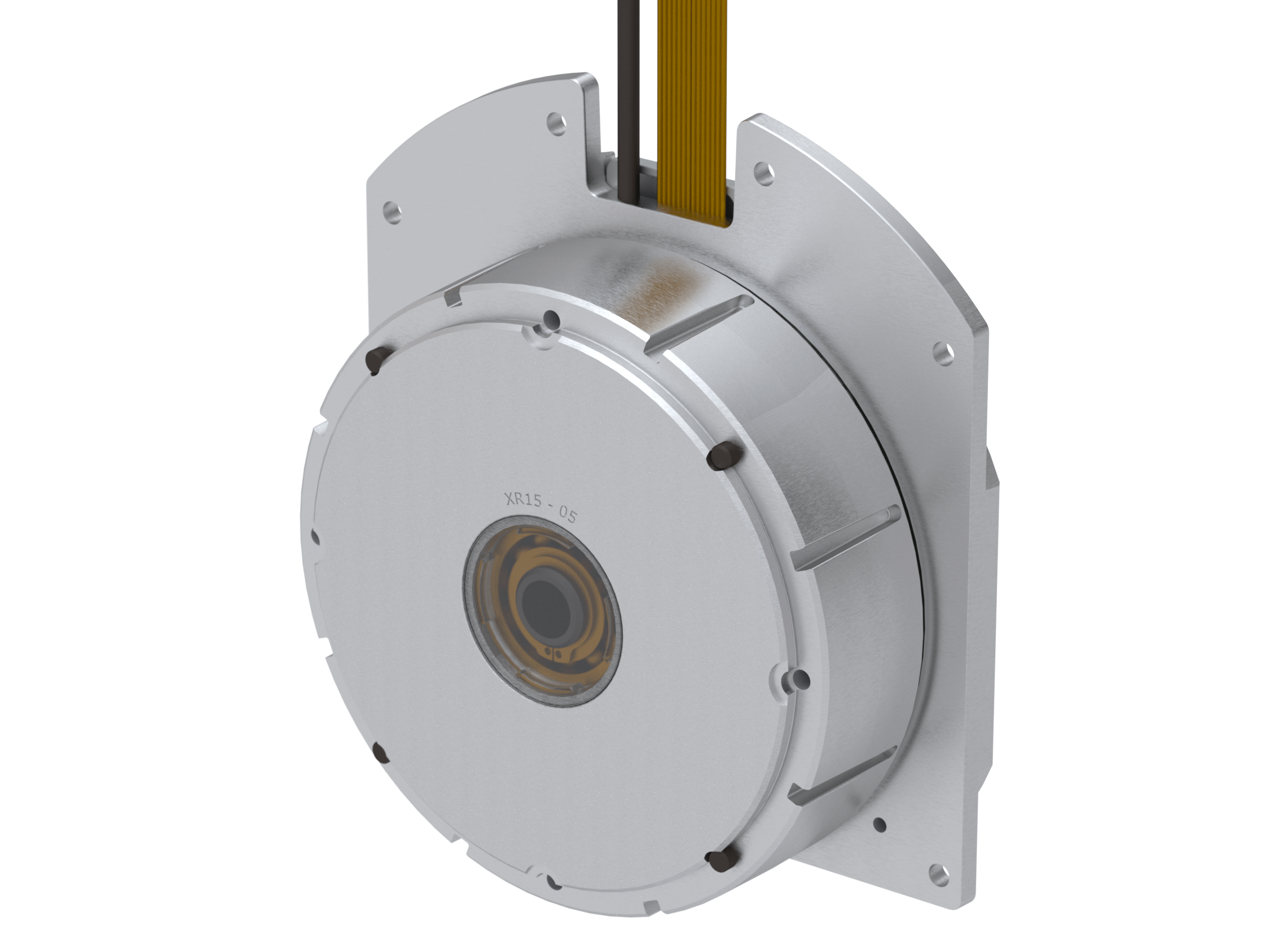

Both brushed and brushless PMW motors are used in many industries. Examples include machining centres, semiconductor manufacturing positioning systems, winders and rewinders in the paper industry, vacuum and other environmental chambers and ovens

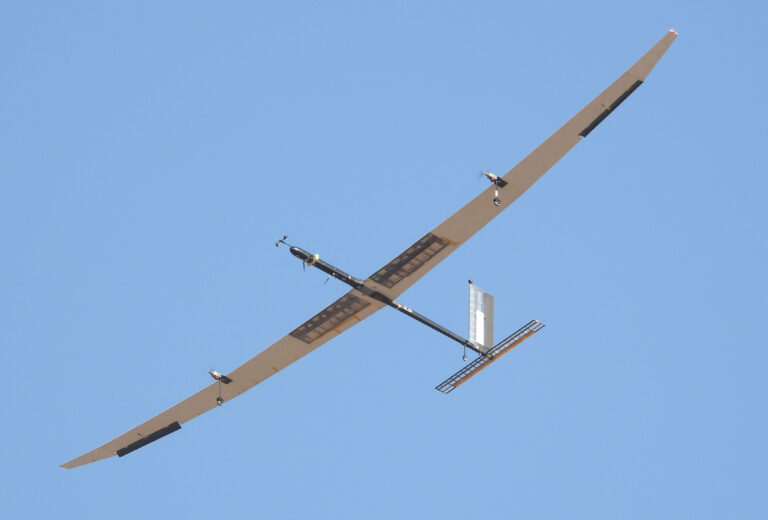

For test and measurement equipment, they can be found in materials testing machines, coordinate measurement machines, sample preparation and polishing devices and other inspection devices. In the field of precision positioning systems, they are used to drive the pan and tilt mechanisms of radio telescopes, coastal and mobile radar dishes and devices for turning turrets.

Get your custom designed motor

Get in touch