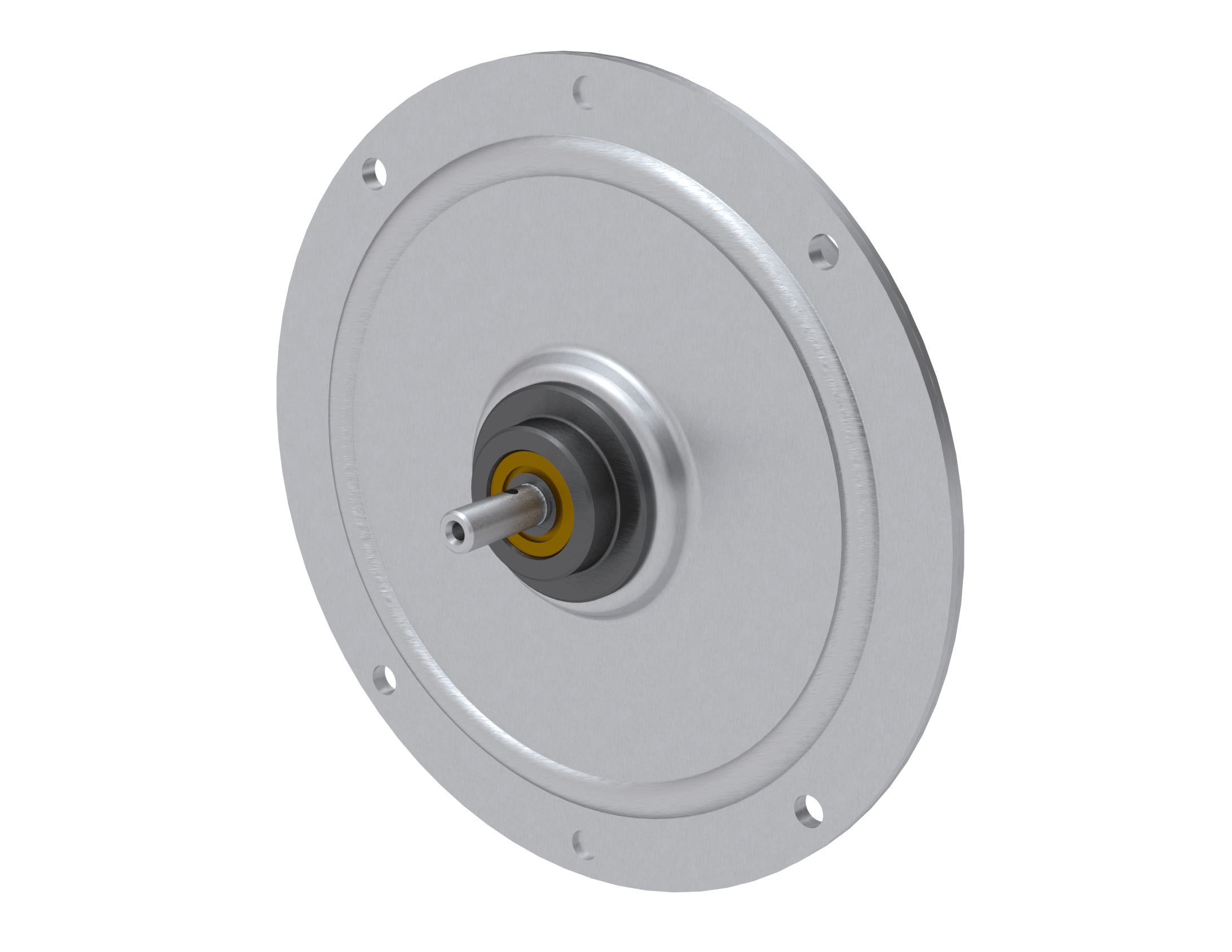

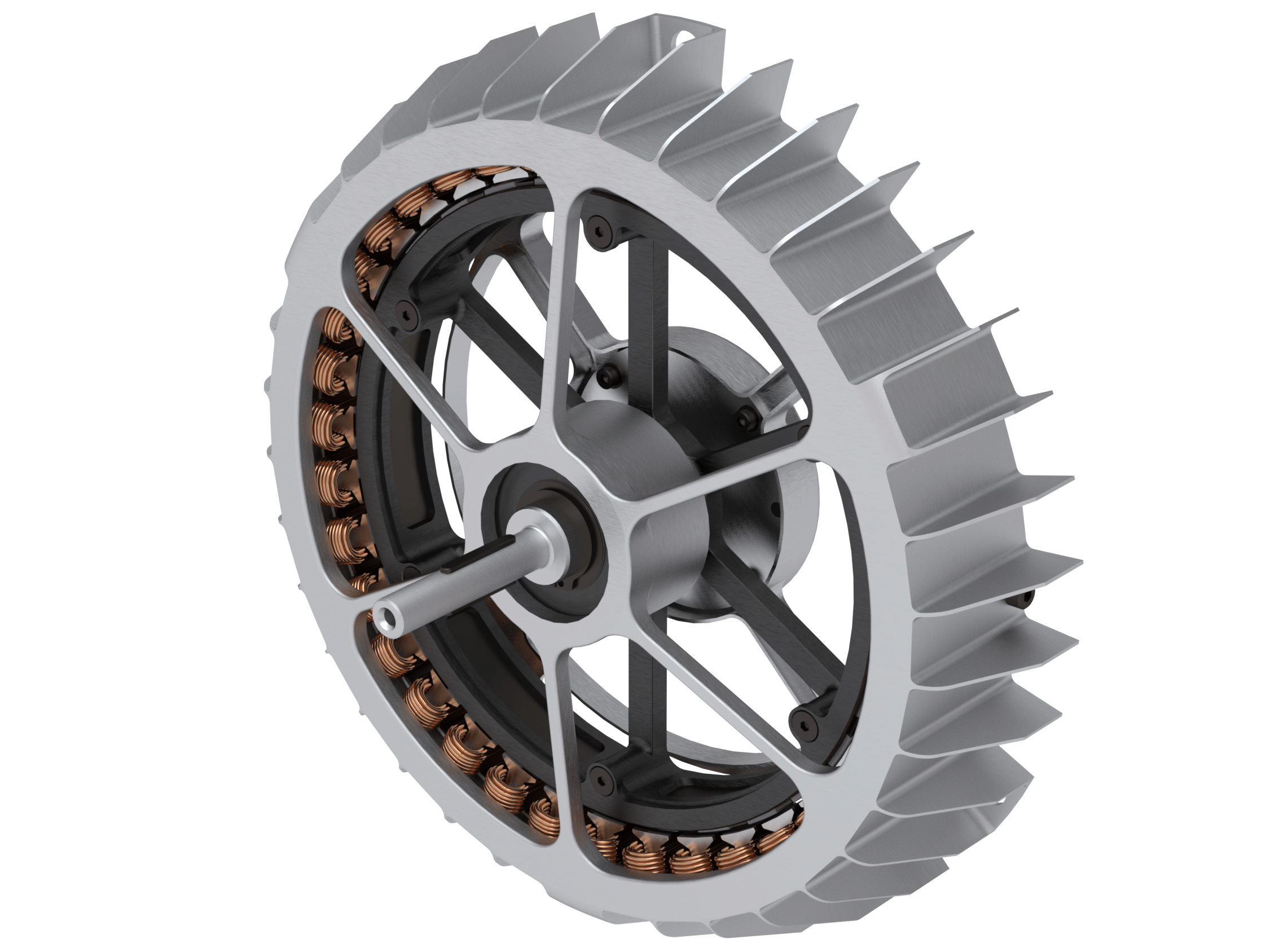

Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

Industry

Medical ...

Servo motors play a critical role in various applications within the medical industry, where precision, reliability, and safety are paramount. The specific requirements for servo motors in the medical industry can vary depending on the application, but here are some common considerations:

Precision and Accuracy Medical equipment often requires precise and accurate motion control. Servo motors should provide high-resolution feedback and precise positioning capabilities. This is crucial in applications such as robotic surgery, where even small errors can have serious consequences

Reliability and Durability Medical devices are expected to operate reliably and consistently over extended periods. Servo motors should be designed for long-term use with minimal maintenance requirements. They should also have a long lifespan and be resistant to wear and tear

Compact Size Many medical devices are compact, and space is often limited. Servo motors should have a compact design to fit within the constraints of the medical equipment

Low Noise and Vibration In medical settings, noise and vibration can be disruptive or even harmful to patients and healthcare professionals. Servo motors should be designed to operate quietly and with minimal vibration.

Cleanliness and Hygiene In applications such as medical imaging or surgical robots, servo motors should be designed to meet cleanliness and hygiene standards. They should be resistant to contamination and easy to clean

Safety and Redundancy Medical devices often require safety features, such as the ability to quickly stop or reverse motion in case of emergencies. Servo motors should support safety features and may require redundancy in critical applications

High Torque and Speed Control Some medical applications, like diagnostic equipment or rehabilitation devices, may require high torque for heavy loads or precise speed control. Servo motors should be selected based on the specific torque and speed requirements of the application

Integration with Control Systems Servo motors should be compatible with the control systems used in medical equipment. This includes communication protocols, feedback devices, and software integration

Cost Considerations While quality and performance are crucial, cost-effectiveness is also important. Balancing performance with cost is a key consideration when selecting servo motors for medical applications

Energy Efficiency Energy-efficient motors can help reduce the operating costs of medical equipment and may be required to meet environmental standards

Customization In some cases, custom-designed servo motors may be necessary to meet specific requirements of a medical device. Customization allows for precise tailoring of the motor to the application

Support and Service Ensure that the manufacturer of the servo motors provides excellent customer support and maintenance services, as downtime in medical equipment can have serious consequences

Get your custom designed motor

Get in touch