Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

NewsSeptember 2023

Advantages of External Rotor Motors

Nick Revels, Applications Engineer, discusses ...

Introduction

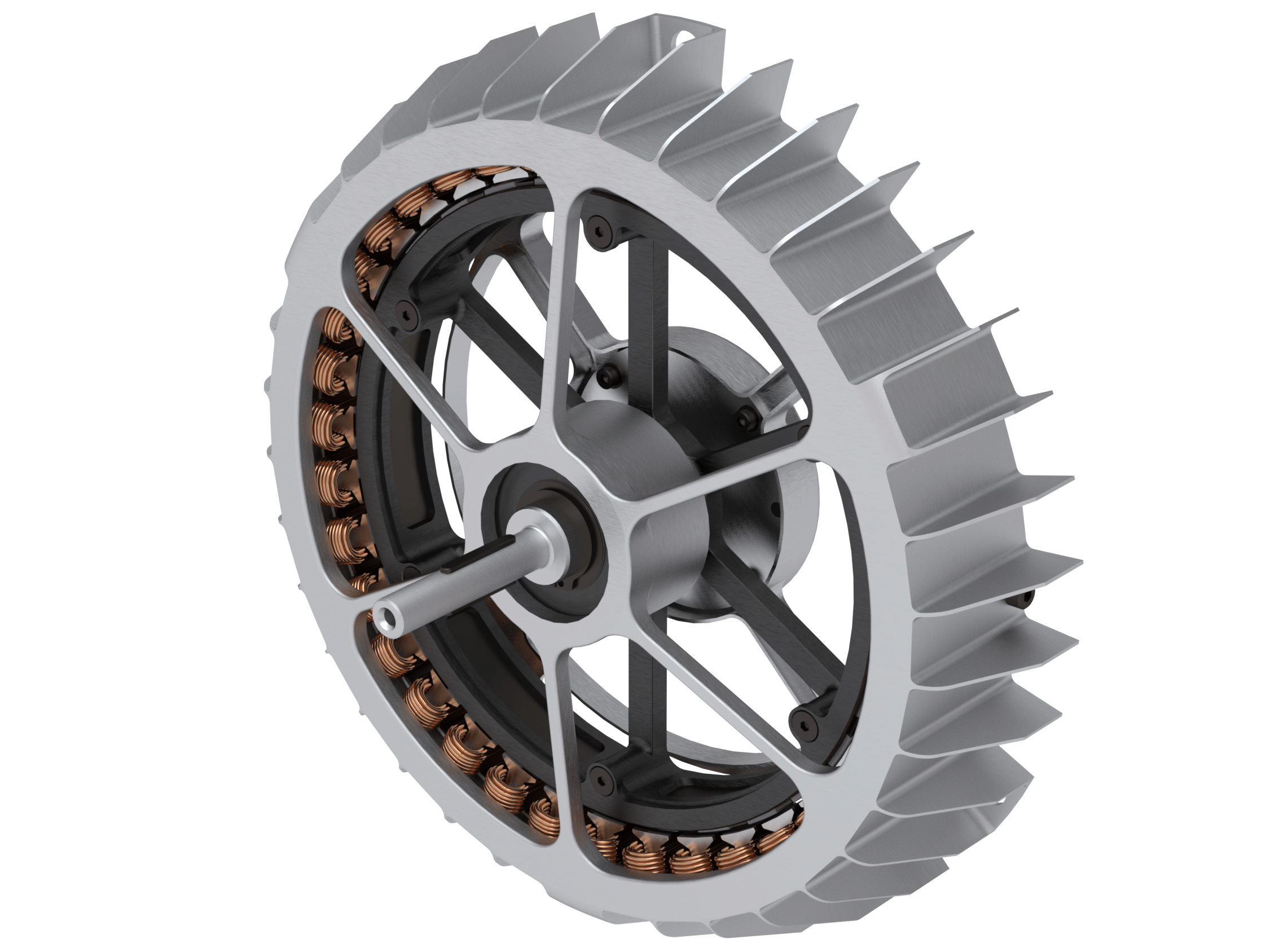

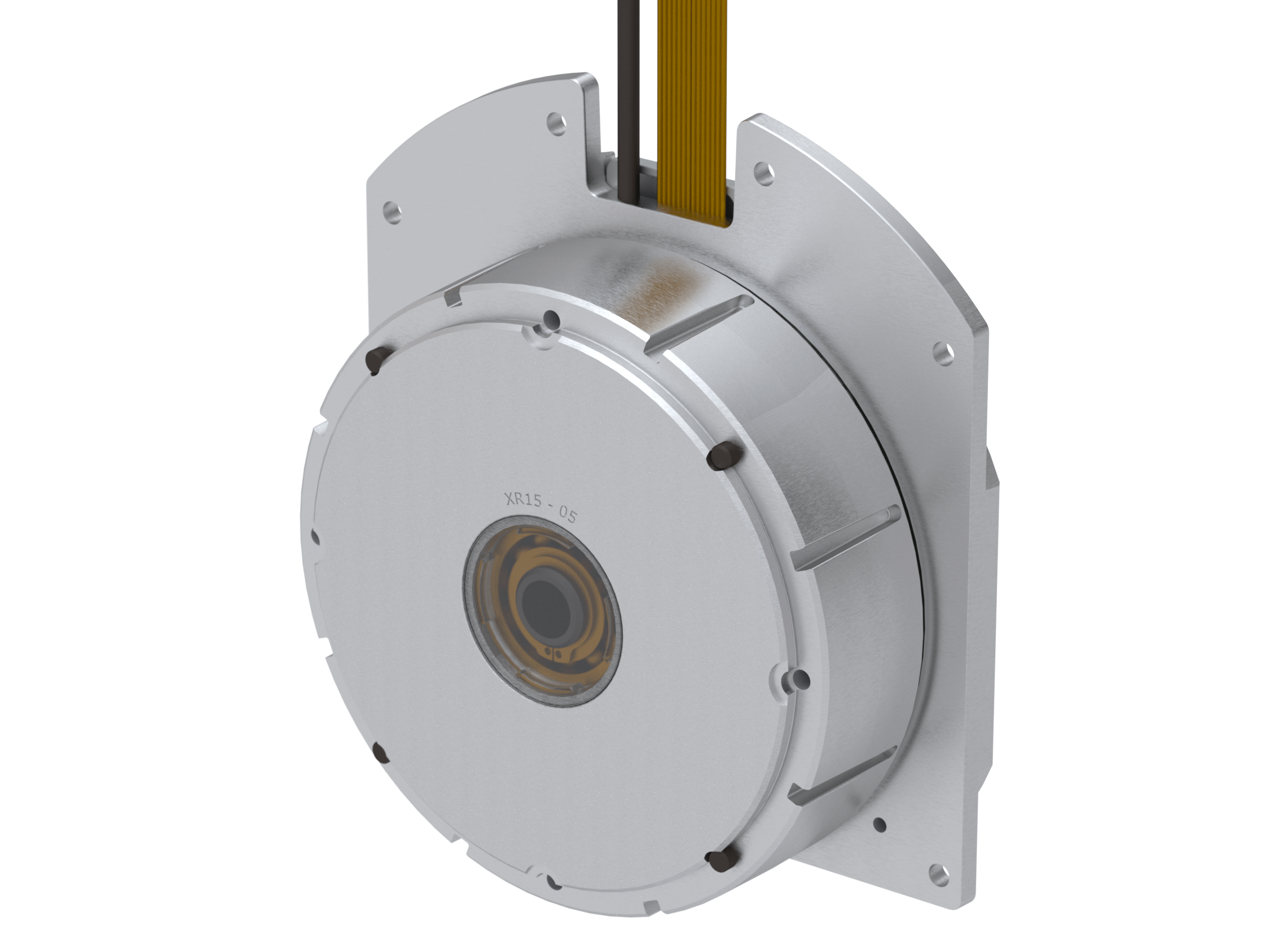

In the world of electromechanical engineering, innovation is key to meeting the ever-evolving demands of various industries. Among the many technologies that have revolutionized the field, external rotor motors stand out as a prime example. These motors, designed and manufactured by companies like PMW Dynamics, have become indispensable in numerous applications due to their unique features and advantages. In this article, we will explore the benefits of external rotor motors and how they contribute to improved efficiency, versatility, and reliability in a wide range of industries

Compact Design

External rotor motors are characterized by their compact design, with the rotor located on the outside of the stator. This arrangement allows for a more efficient use of space, making them ideal for applications where size constraints are a concern. The compact form factor of external rotor motors from PMW Dynamics means they can be easily integrated into tight spaces without sacrificing performance

Enhanced Cooling

Efficient cooling is crucial for maintaining the optimal operating temperature of motors, especially in high-demand applications. External rotor motors have a distinct advantage in this regard. The external rotor design facilitates better heat dissipation, as the rotor is directly exposed to the ambient air. This enhanced cooling capability leads to improved motor longevity and reliability, making them suitable for continuous operation.

High Torque-to-Inertia Ratio

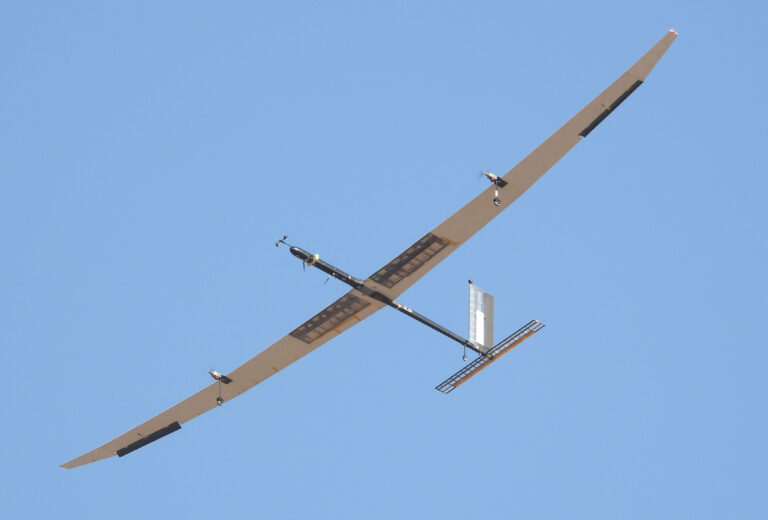

One of the key advantages of external rotor motors is their impressive torque-to-inertia ratio. This means they can deliver high torque levels while having relatively low inertia. This characteristic is invaluable in applications requiring rapid acceleration, precise control, and quick response times. Industries like robotics, automation, and aerospace benefit greatly from this feature, as it allows for more efficient and agile machinery

Versatility in Mounting

External rotor motors are highly versatile when it comes to mounting options. Their design allows for various mounting configurations, such as through-hole, face mounting, and shaft mounting. This adaptability ensures that these motors can be easily integrated into a wide array of applications, from conveyor systems to medical devices, where specific mounting requirements are essential.

Energy Efficiency

Efficiency is a top priority in today's world, and external rotor motors are no exception. These motors, designed by companies like PMW Dynamics, are engineered for high efficiency, reducing energy consumption and operating costs. Their efficient design, combined with advanced materials and manufacturing processes, results in motors that waste less energy as heat, translating into reduced energy bills and a smaller environmental footprint

Quiet Operation

Noise pollution can be a significant concern in many industries, especially in environments where precision and comfort are paramount. External rotor motors are known for their quiet operation. The external rotor design reduces vibrations and noise, making them ideal for applications such as medical equipment, HVAC systems, and consumer electronics, where noise levels must be minimized

Low Maintenance

External rotor motors are designed with durability in mind. The simplicity of their construction means there are fewer components that can wear out or fail. This leads to lower maintenance requirements and reduced downtime, which is critical in industrial settings where productivity is key

Conclusion

External rotor motors, like those crafted by PMW Dynamics, offer a multitude of advantages that make them indispensable in various industries. Their compact design, efficient cooling, high torque-to-inertia ratio, versatility in mounting, energy efficiency, quiet operation, and low maintenance requirements make them a top choice for engineers and manufacturers seeking reliable and efficient motor solutions. As technology continues to advance, external rotor motors are likely to play an even more prominent role in powering the machinery that drives our modern world

Want to find out more?

Get in touch