Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

NewsSeptember 2023

Alnico Magnets: A Time-Tested Choice for Motors

Richard Bulley, PMW Dynamics Engineering Manager, discusses ...

Introduction

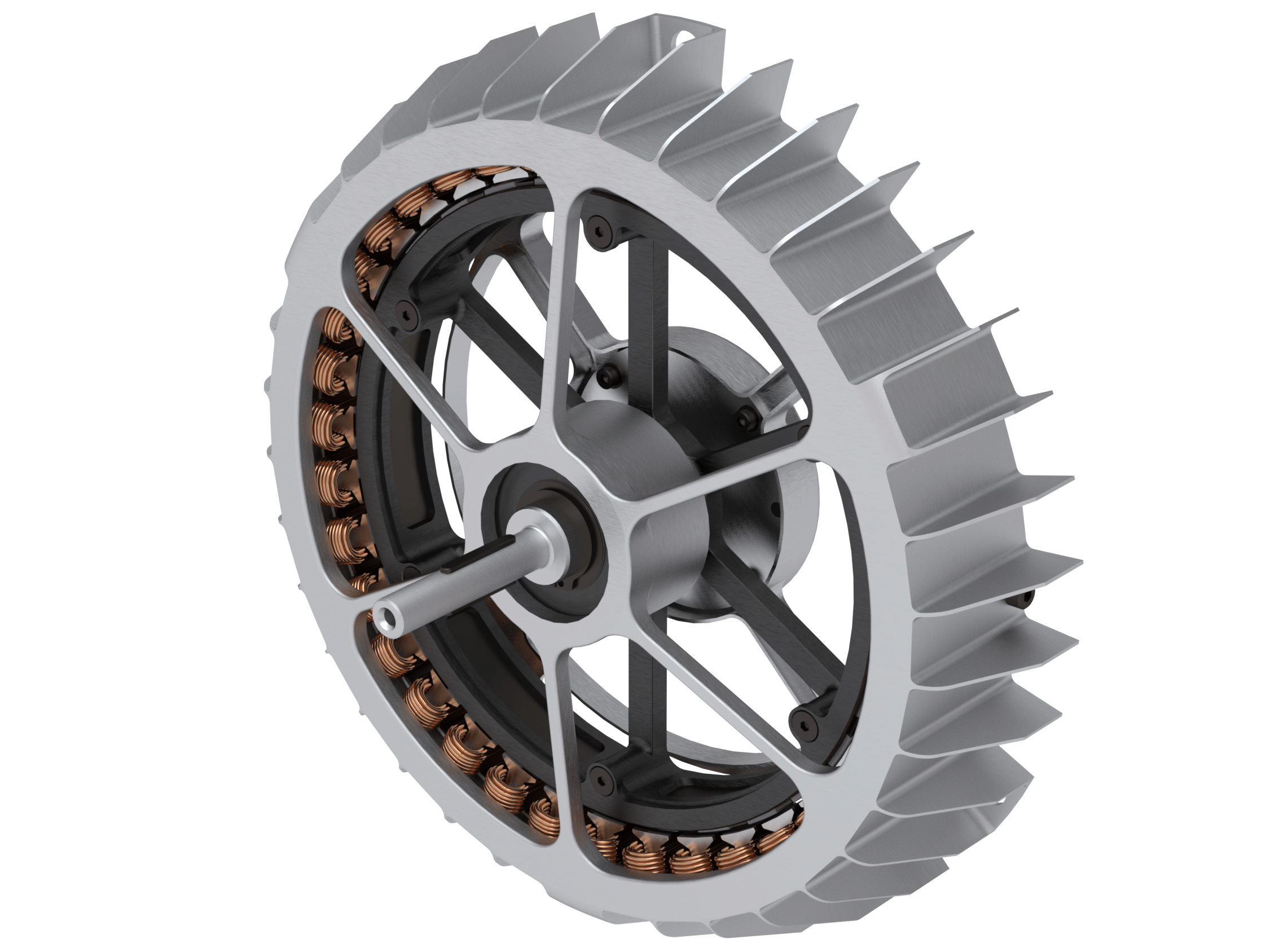

When it comes to choosing the right material for magnets in electric motors, the options may seem overwhelming. Neodymium, ferrite, and samarium cobalt magnets have all made strides in recent years. However, one often overlooked but still highly valid choice is Alnico (an abbreviation for Aluminium, Nickel, and Cobalt) magnets. Despite the emergence of newer magnet materials, Alnico magnets remain a reliable and valuable option for motor applications

History and Legacy

Alnico magnets have a long and storied history in the world of magnetism. They were first developed in the 1930s, and their continued use in various applications is a testament to their durability and effectiveness. This long history has allowed engineers to fine-tune their properties and understand their behaviour in different environments

Temperature Stability

One of the key advantages of Alnico magnets is their exceptional temperature stability. They can maintain their magnetic properties in extreme temperature conditions, making them suitable for motors that operate in high-temperature environments. Unlike some newer magnet materials, Alnico magnets do not suffer from significant losses in magnetic strength when exposed to heat

High Magnetic Strength

Alnico magnets are known for their high magnetic strength. They offer strong magnetic fields that are crucial for efficient motor performance. This characteristic makes them ideal for applications that require high torque, such as in industrial motors or generators

Resistance to Demagnetization

Demagnetization, or the loss of magnetic strength over time, can be a concern in some magnet materials. However, Alnico magnets exhibit excellent resistance to demagnetization, ensuring long-term reliability in motor applications. This resistance is particularly valuable in applications where consistent and stable magnetic properties are essential

Customizable Shapes

Alnico magnets are relatively easy to manufacture into various shapes and sizes. This flexibility allows engineers to design magnets that fit specific motor configurations and requirements. Whether you need ring-shaped magnets for rotor applications or custom shapes for specialized motors, Alnico can be tailored to suit your needs

Excellent Corrosion Resistance

Alnico magnets have good corrosion resistance, which is crucial in applications where exposure to moisture or corrosive environments is a concern. This property extends the lifespan of motors using Alnico magnets and ensures their continued performance over time

Alternative to Rare Earth Magnets

While neodymium magnets, a type of rare earth magnet, have gained popularity due to their high magnetic strength, Alnico magnets can provide a viable alternative in certain situations. Alnico magnets can offer comparable performance and temperature stability without relying on rare earth elements, which have limited availability and can be subject to price fluctuations

Conclusion

In conclusion, Alnico magnets have stood the test of time and remain a valid choice for magnet materials in motors. Their long history, temperature stability, high magnetic strength, resistance to demagnetization, customizable shapes, excellent corrosion resistance, and potential as an alternative to rare earth magnets make them a reliable and practical option for a wide range of motor applications. While newer materials have their merits, Alnico's proven track record and unique properties continue to make it a valuable choice for engineers and designers seeking dependable magnet solutions for their motors

Want to find out more?

Get in touch