This is just one of a host of successful designs engineered by PMW Dynamics

NewsNovember 2022

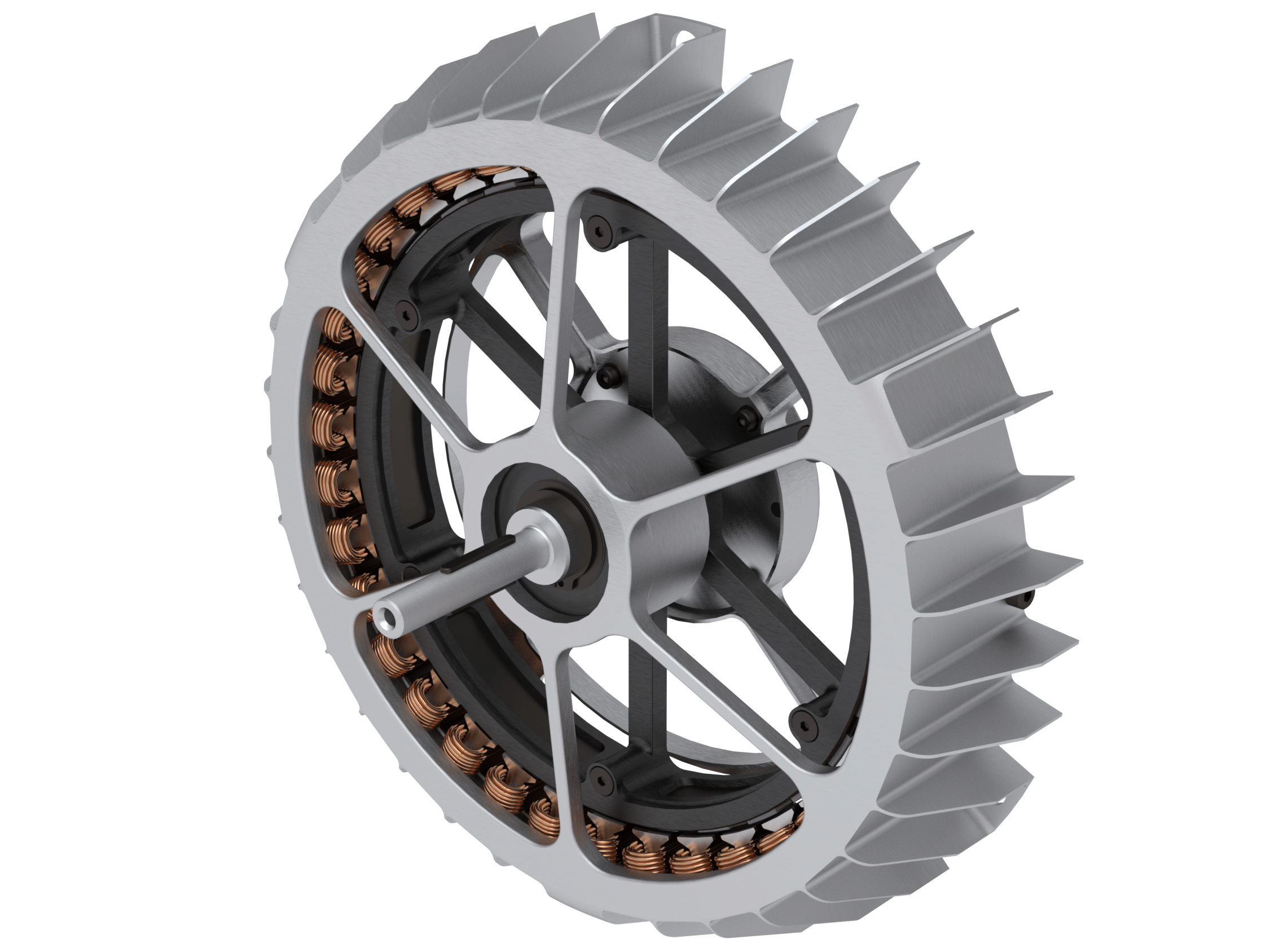

Outer Rotor Motor Designs

In the latest of the "Ask Ian" series, PMW Dynamics' Technical Manager, Ian Matthews Golledge, compares inner and outer rotor brushless motor configurations

Ian Matthews Golledge - Technical Manager at PMW

What’s an outer-rotor-motor, Ian?

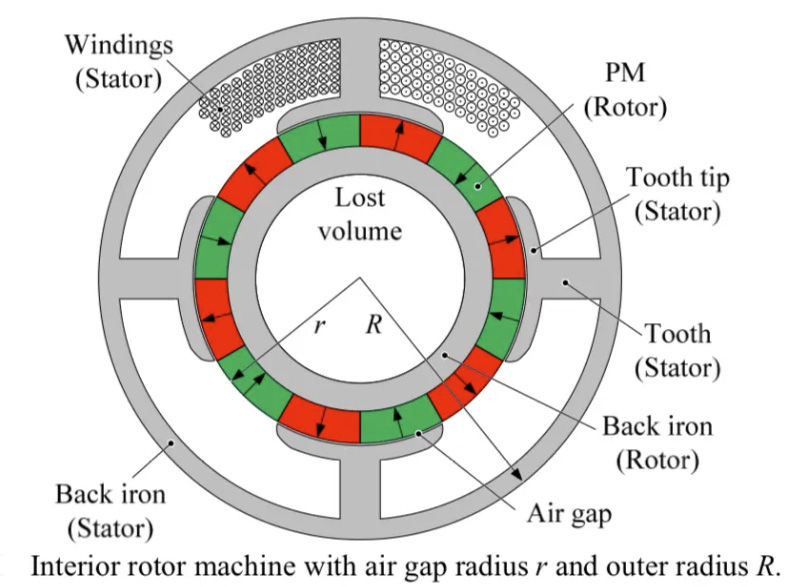

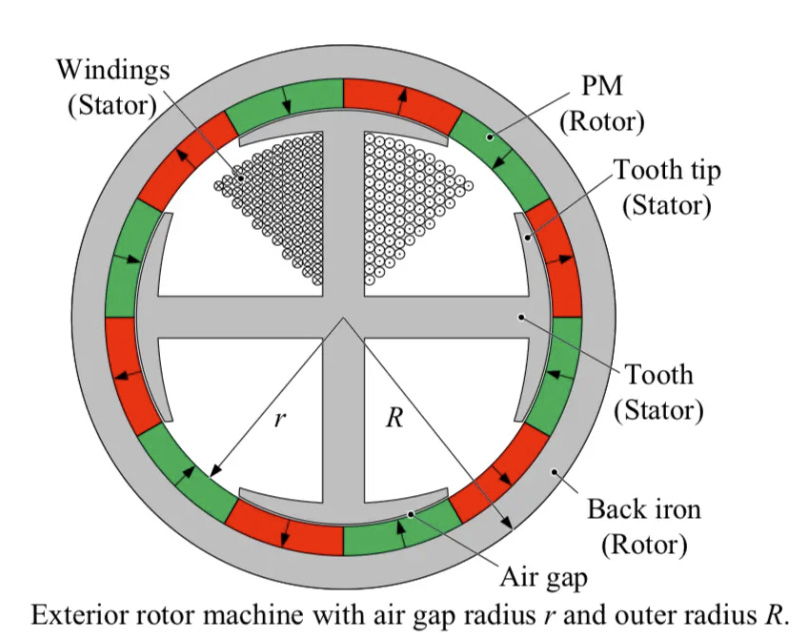

Conventionally, the inner element of a electric motor rotates whilst the outer element is stationary. However, with an outer rotor motor design this is reversed. The stationary element, the stator, in central to the motor and the revolving element, the rotor, rotates around the stator

Ian, how is an outer-rotor-motor constructed?

The stator consists of a stack lamination of electrical steel arranged in a circular design with individual “teeth” arranged radial around the inner core. Each tooth has an individual copper winding traditionally connected in a “delta” configuration with three wires exiting the assembly for connection to the drive electronics.

The rotor consists of a steel ring onto which individual magnets are adhered to the inner diameter arranged in an alternative North-South and South North pattern.

The stator is stationary, and the rotor revolves around the stator. The speed, direction and torque output from the motor are all fully controllable.

Inner Rotor Design - Need better image

Outer Rotor Design - Need better image

What are the advantages of outer rotor designs?

A significant contributory factor to motor performance, from a torque perspective, is motor’s active diameter. With the outer rotor design presenting the motor effectively inside-out, this moves the positioning of the air gap further from the centre-of-rotation. This increase in operating radius is directly proportional to ability of the motor to generate more torque proportionally than a comparably sized inner rotor design

So, Ian are there any disadvantages?

All motor generate heat as a function of operation. Typically, the heat is development in the stator winding. With the winding now embedded in the centre of the motor, cooling of the motor needs to rely more on conduction and somewhat less on convection as a means of extracting heat from the motor

Where would you use an outer rotor motor design?

A wheel drive for an AGV is a very good example. The stationary part of the motor (stator) can bolt directly to the very chassis whilst the wheel (and tyre) can be mounted directly on the rotor resulting a simple, cost effective and high-efficient package

Are outer rotor motors readily available on the market?

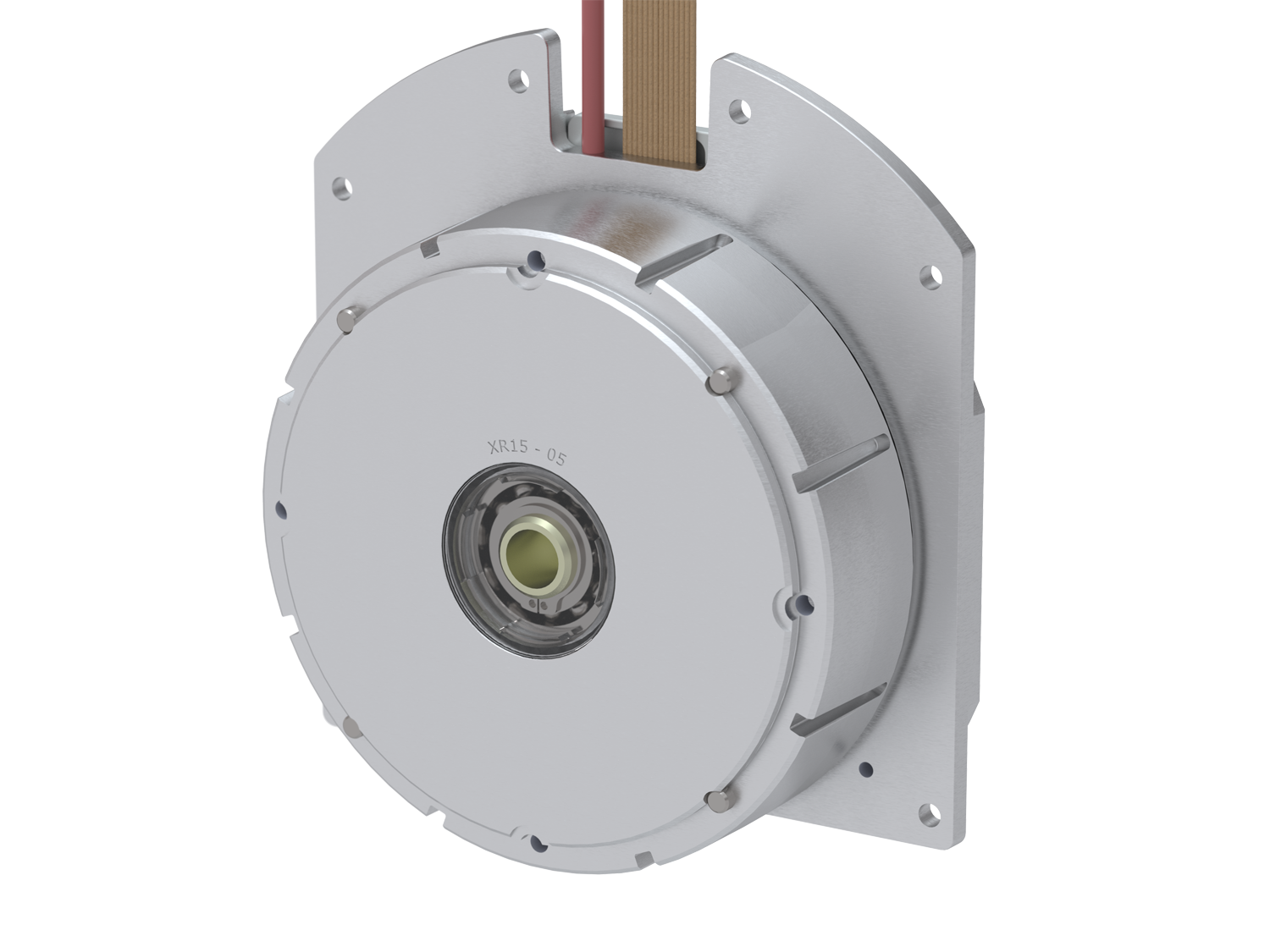

Outer rotor motors are generally not so prevalent on the market as conversational inner rotor design, however PMW Dynamics boasts a broad capability in this regard

Driven by extensive research and development of in-wheel automotive motor solutions, PMW Dynamics adapted and deployed 10,000’s of outer rotor motors in numerous applications. Outer rotor configurations lend themselves particularly suitable for low-length, pancake packages providing the perfect solution for AGV wheel drives (compact, high torque, low speed, direct drive)

Outer Rotor Warehouse Robot Wheel Drive by PMW Dynamics

Want to find out more?

Get in touch