Advanced Servo Motors ...

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

NewsJune 2024

Flying High with British Technology

PMW Dynamics are delighted for this interesting application to have been selected by Drives & Controls Magazine to feature in their recent motor supplement in May '24 edition

PMW Dynamics have a rich heritage of 60+ years designing and manufacturing specialist motors for demanding commercial, industrial, defence and aerospace applications. Based from our global HQ in Hampshire, UK, and deploying the latest in design, simulation and analysis tools, our motor design and manufacturing teams have extensive experience with literally hundreds of successful design and build applications in daily service across multiple market sectors including automotive, medical, aerospace, defence, robotics and factory and warehouse automation

Many requirements for motors can be realised by utilising standard off-the-shelf catalogue motors. And, when they can, this is often the most cost effective solution even if there are some minor compromises to accept. However when they can't or when these compromises are too great, perhaps the optimum solution is a bespoke motor design

Read how PMW Dynamics resolved the significant technical challenges for this high altitude, long endurance aerial platform ...

Drives & Controls, May 2024

Drives & Controls, May 2024

Drives & Controls, May 2024

Alternative read on-line at Drives & Controls Magazine

Below is a transcript of the article from Drives & Controls ...

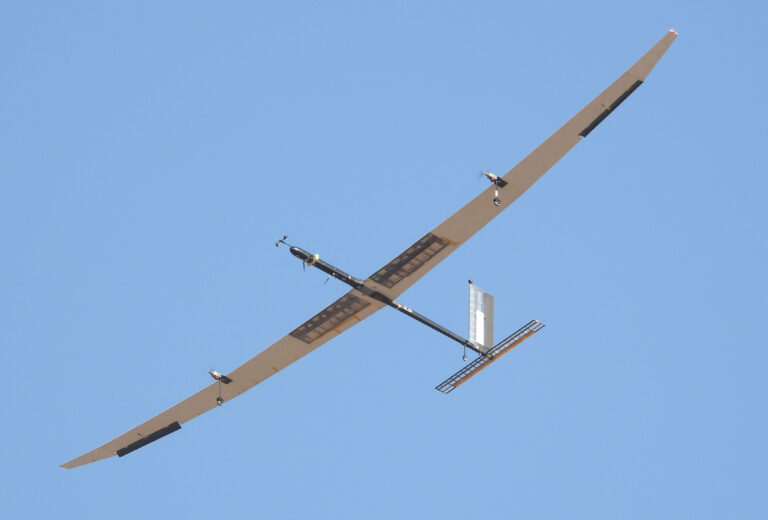

Last summer, a British-designed, solar-powered aircraft flew for many hours at a height of 20km, establishing itself as a cost-effective alternative to traditional airborne and satellite surveillance systems. Ian Matthews Golledge, Technical Manager at the Hampshire motor manufacturer PMW Dynamics, explains some of the factors that went into designing the aircraft’s custom motors.

Unmanned aerial vehicles (UAVs) aren’t new. They’ve been around, in one form or another, since the late 18th century. The British De Havilland DH.82B Queen Bee, which flew for the first time in 1935, has been described as first modern UAV. The term “drone” is thought to acknowledge this ground-breaking aircraft.

Fast-forward about 85 years and another British company is developing an ultra-lightweight, solar-powered craft that can fly at high altitudes for several months at a time, without needing to refuel, offering a cost-effective alternative to conventional sensing and communications systems.

The Phasa-35 (Persistent High Altitude Solar Aircraft) is being developed by Hampshire-based Prismatic, which is part of BAE Systems. It is designed to fly at stratospheric altitudes above 20km (more than twice the height of Mount Everest), carrying out duties such as military surveillance, disaster relief, environmental monitoring, border protection, and providing mobile and Internet communications for remote areas. At this height, in the outer reaches of the planet’s atmosphere, the craft is above the weather and conventional air traffic.

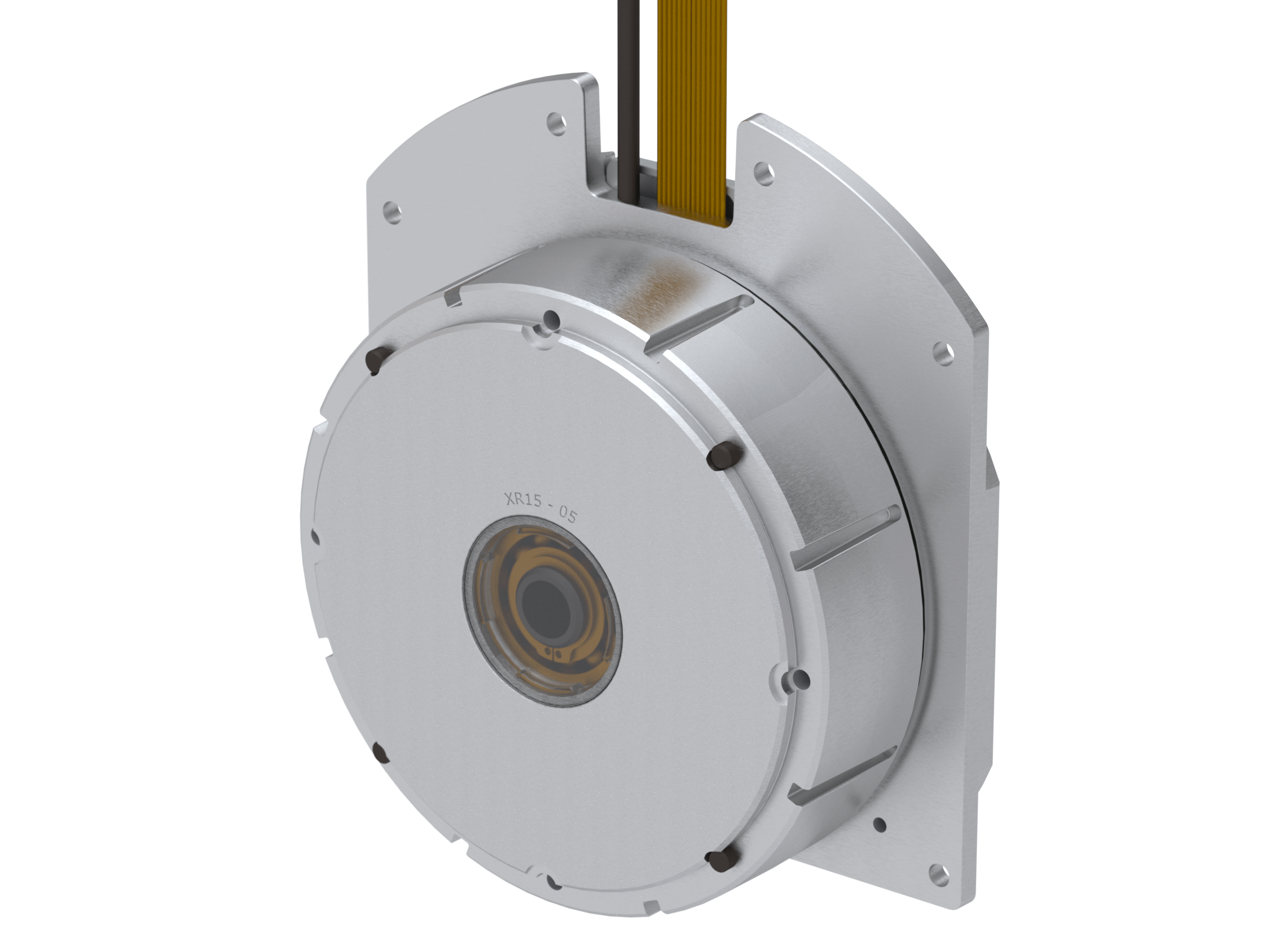

The unmanned craft – technically a High Altitude Pseudo Satellite (HAPS) Unmanned Aerial System (UAS) – has a 35m wingspan, weighs just 150kg and can carry a 15kg payload. Photovoltaic arrays on the wings provide energy during the day, which is stored in rechargeable cells to maintain flight overnight. The UAV’s two motors are a critical element of the design.

In 2017, Prismatic approached PMW Dynamics to help develop the propulsion system. PMW has a long history of working on novel applications for customers in a variety of markets, and we jumped at the chance to flex our engineering muscles. PMW and Prismatic have worked closely to achieve truly exceptional engineering.

We often meet customers who think they know what they want, but do not really understand what they need. Prismatic was not like that. Its engineers knew exactly what they wanted the propulsion motors to do.

Efficiency, mass and losses - the challenge was always about efficiency. But efficiency isn’t just about energy out vs energy in, and the many variables that make up a motor’s loss profile. In an aircraft, it’s also about mass. Every part of an aircraft influences its design and performance. In the Phasa-35, mass is even more critical than in a conventional aircraft. Every gramme of mass affects the maximum duration of its missions, or its maximum payload.

But there’s more – there’s a correlation between mass and efficiency. If mass is very low, efficiency may be sacrificed to a degree, or vice versa. A super-light motor that doesn’t have class-leading efficiency may be adequate – the same as a super-efficient, but slightly portly, motor could be. As with any application, it’s critical to achieve the right balance and, for this application, to carve out the boundaries that limit the balance. What we needed was a super-light motor that’s super-efficient.

Fortunately, the Prismatic team understood the relationship between mass and efficiency. That constrained the limits we could work within, which was a good thing. By reducing some of the many variables and focusing on what really matters, we saved time and effort in the development.

Selecting the most appropriate materials and components for the application was not easy. The Phasa-35 is designed to fly 24 hours a day and it’s extremely cold at an altitude of around 20km at night. Conversely, during the day, solar radiation is significant. The thermal management of the motor is complex, but vital, because every Watt that can be shed by good thermal management reduces the temperature of the motor, which in turn reduces the electrical losses and increases efficiency.

It is common to talk about system efficiencies, but that doesn’t tell the whole story. For an electric motor, running at low speeds and high torque, the efficiency is relatively low. As the speed increases, the losses don’t generally increase much, but the output does, so efficiency climbs. That’s why extremely power-dense motors run at high speeds – 10,000s of rpm. The Phasa-35 propulsion motors are not like that; they run at quite modest speeds.

It is important to understand what influences efficiency – where the losses occur and why. For example, losses in the electromagnetically active components are affected by the operating temperature. For electrical steels, the losses decrease as temperature rises. For electrical conductors, it’s the other way around – low temperatures reduce losses. Fortunately, the losses in the conductors dominate, so low temperatures work for us. Shedding heat through good design (electromagnetic and mechanical) reduces the temperature of the motor which, in turn, reduces losses, increasing potential mission capabilities.

Commutation - mass and efficiency reared their heads again here. We wanted super-lightweight sensors. They don’t come much lighter than digital Hall devices, but these don’t provide the most accurate switching points, leading to losses. Resolvers are often used in harsh aerospace applications, but they are relatively heavy.

For this application, we chose an RLS encoder that provides accurate switching, but is also lightweight and has low power consumption. Usually, silicone-based systems won’t operate below -40°C, but with some clever thermal management, the Prismatic team overcame this problem.

In February 2020, the Phasa-35 completed its maiden flight in Australia. The data gathered during the flight provided invaluable data, which was used to correlate actual performance with mathematical modelling and ground testing.

On 25 June 2023, the Phasa-35 climbed to more than 66,000ft above New Mexico in the US, and held this altitude for about four hours, until sunset, before descending overnight to land first thing in the morning. This flight has provided more insightful data, which is being used to construct a digital twin, as well as to inform ground-based testing.

The first motors that propelled the aircraft performed as expected. This has resulted in data being fed back into the base model for the motor electromagnetics, which will improve the design of future generations of motors.

Since last year’s stratospheric flight, PMW and Prismatic have been working on upgrading the motors. The aim has been to improve the climb rate and efficiency at altitude, to stretch mission capabilities even further. It’s been an interesting journey with a potentially patentable development. Hopefully, that will be the subject of another article in a year or two.

PMW Dynamics and Prismatic continue to work closely together, modelling, testing, developing and building for the next generation of Phasa-35 propulsion systems – but the specifications are highly confidential!

END

Want to find out more?

Get in touch