NewsMarch 2025

Adam Birch contrasts unique, bespoke motor development with expert tailoring of Savile Row

The first three months of this year here at PMW Dynamics we’ve done a lot of work regarding custom motors for customers. I found myself presenting the various services that we can provide as a bespoke motor designer and manufacturer. However I’ve been called up on by my partners and resellers around the world on something and I thought it was probably worth addressing here.

I deal with a great number of very experienced resellers all around the world and work in variety of languages and it’s been brought to my attention that I use the word “bespoke” and I use the word “custom”.

Now, as a native English speaker I actually make a distinction between the word custom and the word bespoke but I’ve been told that in other languages they are interchangeable words. This has caused a bit of confusion as here at PMW Dynamics we do actually offer both a bespoke and a custom motor design service. So, for the sake of clarity and not wishing to get into any semantic arguments, it’s probably about time that I rolled out an old analogy I’ve been using since I joined the company. I think it pretty much covers how we can work with our customers.

I tend to think of PMW Dynamics a little bit like a tailor shop. You can come and see us with your specific requirements and there are a number of ways that we can get you a motor that suits you the most (yes, there’s going to be a lot of tailoring puns in this article).

Pret-a-“Motor”

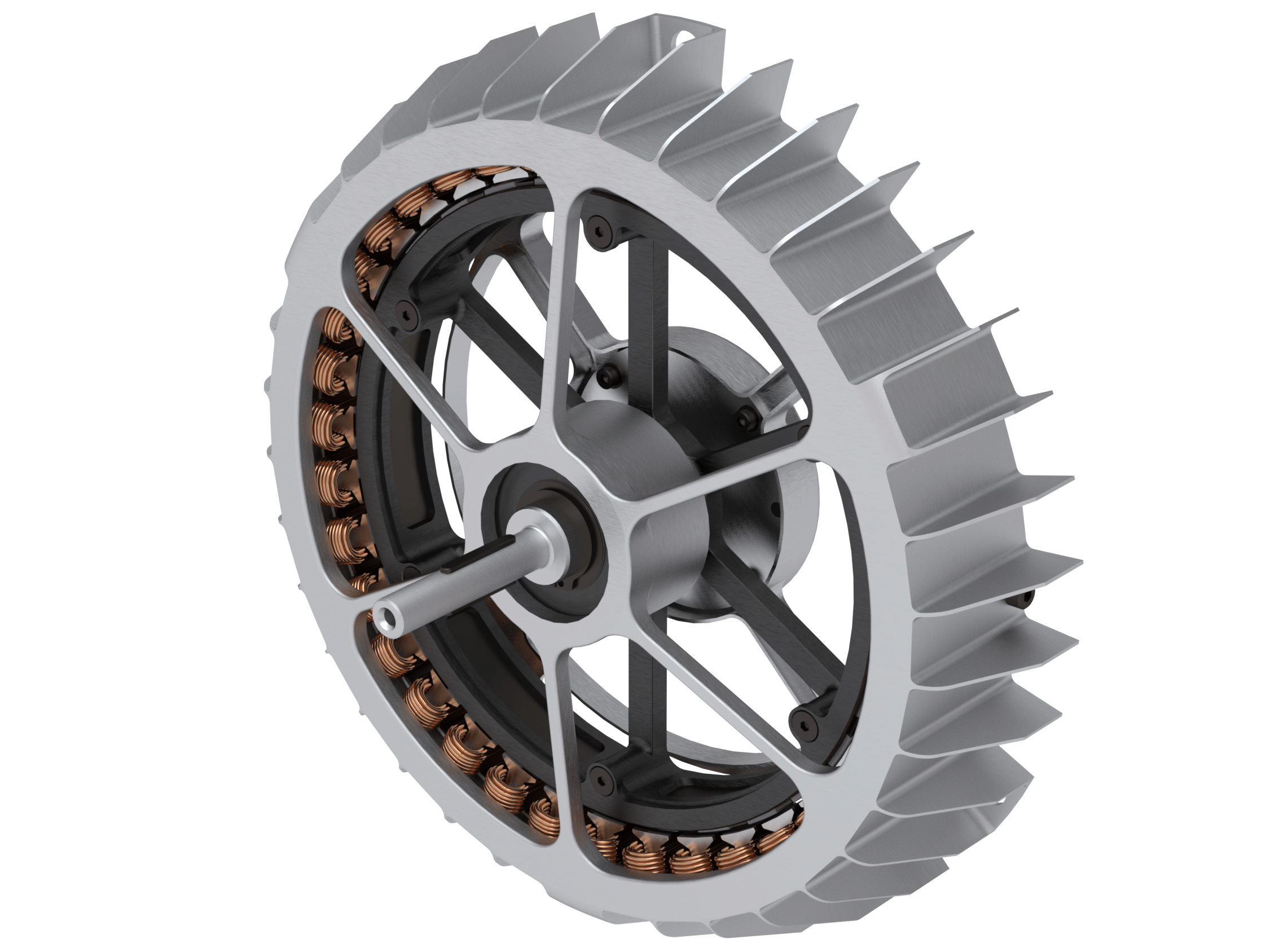

First off we have the easiest way. A customer comes to us with a specific set of requirements for their motor; be that voltage, RPM, torque or size. The first thing that we can do is look at some of the frameless and cased motors that we have in stock as part of our ready-to-wear collection.

Customers can simply pick the one that’s the best suited to them and that’s it, nice and easy. In most cases though, this is not really why a customer will come to see us at PMW and usually they’ve come to see us as because they cannot find something that is just ready to go off-the-shelf and need something a little bit more… tailored

Custom

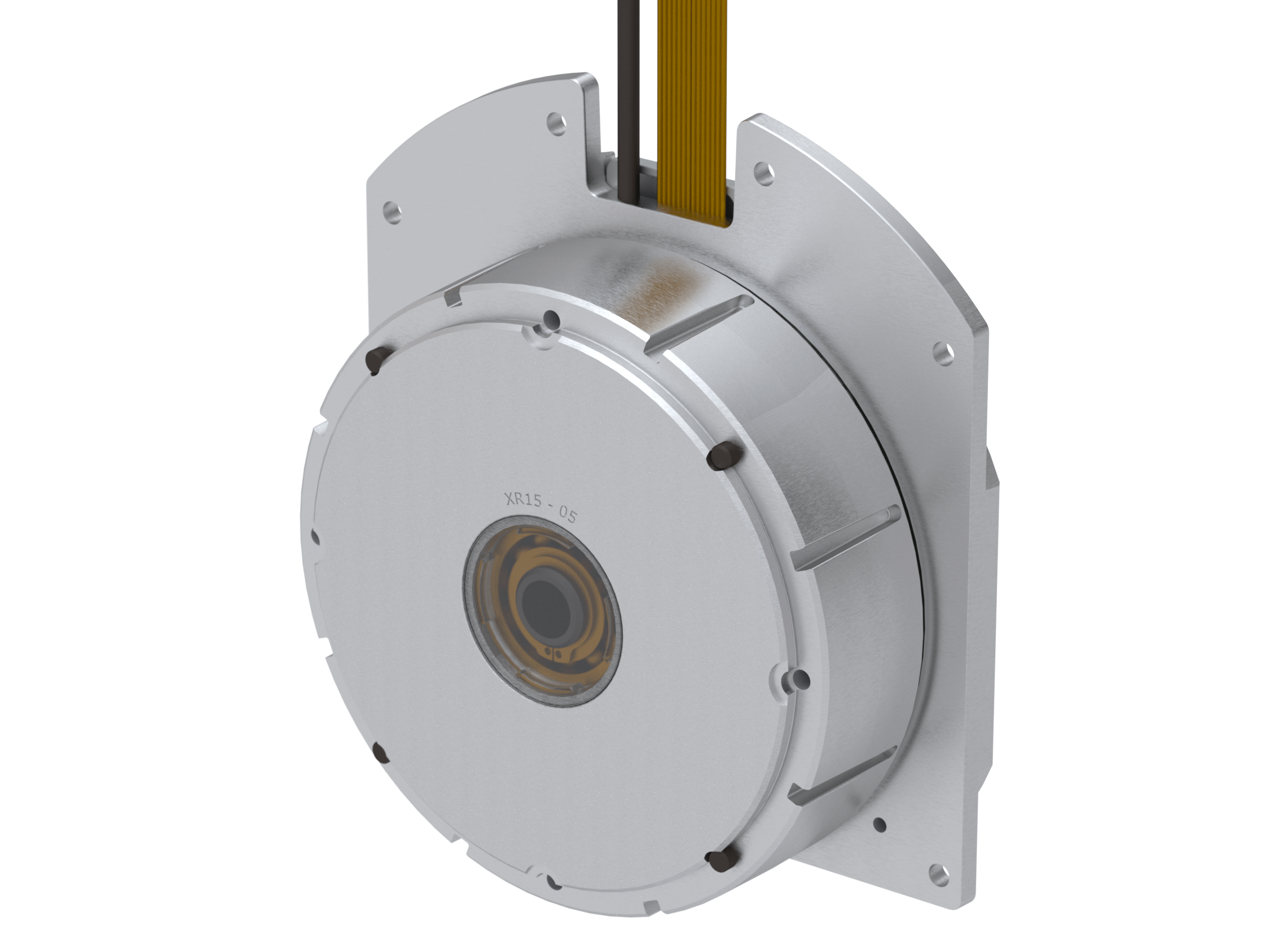

This is the distinction I would make between custom and bespoke. Custom is taking something that we’ve got as an off-the-shelf motor and make some adjustments to it. Some motors can be adjusted quite easily in terms of their operating voltages or other aspects of their performance. We can make subtle differences to an existing design so that it suits the requirements for example, turning a motor that is designed to run at 48V DC and making it run on 24V DC is a relatively easy process . Also making a motor of the same size run slightly faster or slightly slower is something that we can do by altering the winding of the motor and this can be done by our team here. So using my tailor analogy again, it’s really a question of picking something off the rack and then making some slight modifications maybe just changing the buttons or adjusting the sleeves. It takes a little bit more time to do this work but generally speaking you’ll get the perfect fit.

Suit up

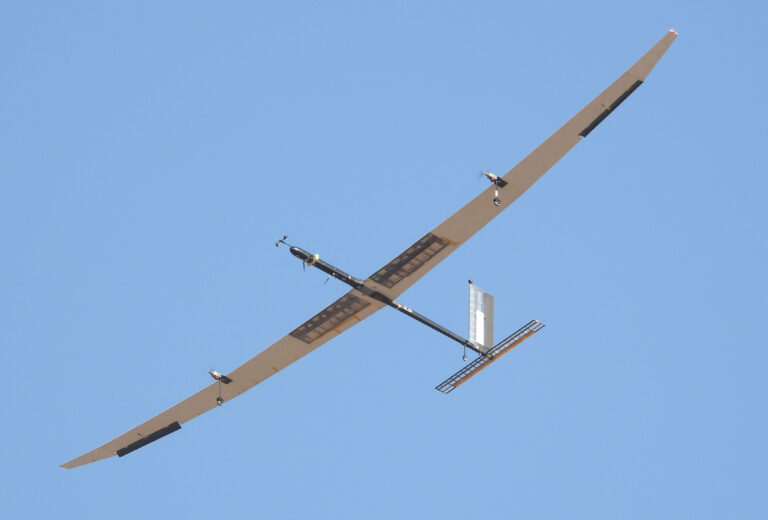

And then we’re onto bespoke and this is the real special skill of PMW Dynamics. We can take a customer from a blank piece of paper to a fully realised designed. We will walk through the process get a full understanding of their requirements model the motor and make sure that it is able to do exactly what the customer requires. We can also put in such considerations such as operating temperature if it’s environment has special requirements.

From here, we design the motor, rapidly prototype it so that the customer can test a real world version before we go into full production and produce any number that the customer may require per year. This is the real tailored experience in terms of we would take your exact measurements, we create your suit from whole cloth, stitch it together, check that it fits, make any adjustments to ensure that it is a perfect fit for your needs.

The level of tailored service required depends on the customer’s needs. We offer a range of off-the-shelf motors, including the IG 9190, designed specifically for the AGV/AMR market, as well as various frameless motors ideal for robotic applications—from small robot arms to large wheel solutions. Customers can often find a suitable option from our standard selection. However, if a standard motor doesn’t meet their requirements, we can easily customize it within certain limits. For truly unique specifications, we excel in developing bespoke solutions.

So I suppose my analogy does kind of work in this case. We can offer you all kinds of bespoke (or custom) services depending on your specific requirements. Some may take a little bit longer to produce than others but I suppose that’s to be expected when you’re tailor making a product.

After all this tailoring talk, I think it’s time I was better dressed around the office. I’m usually wearing a pair of jeans but I suppose I should probably wear a suit from now on.

Want to find out more?

Get in touch