Advanced Servo Motors ...

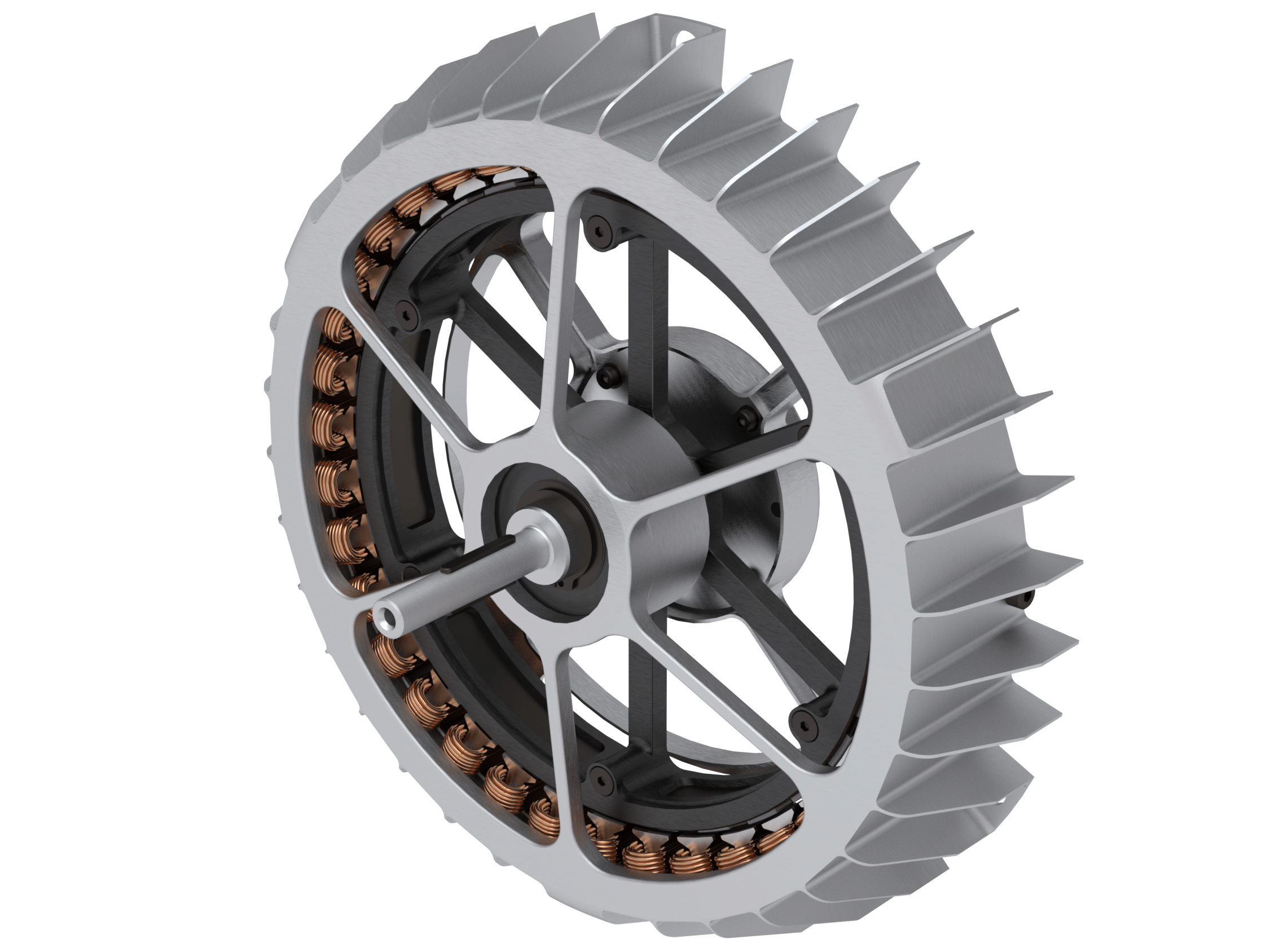

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

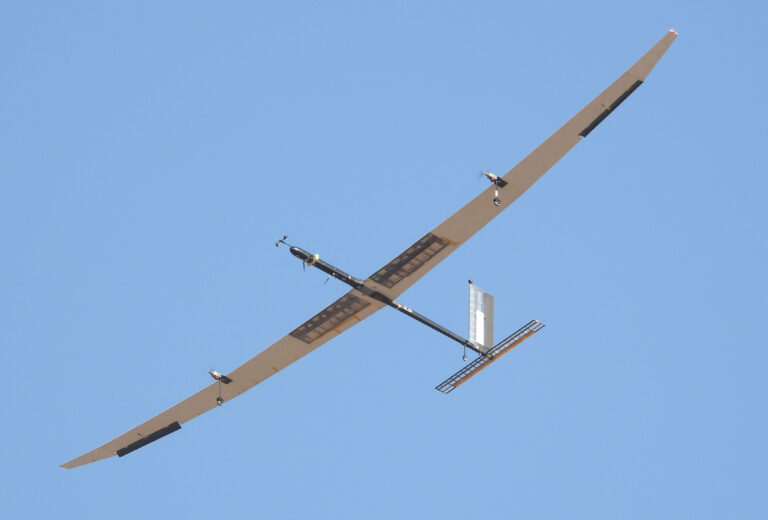

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

NewsSeptember 2023

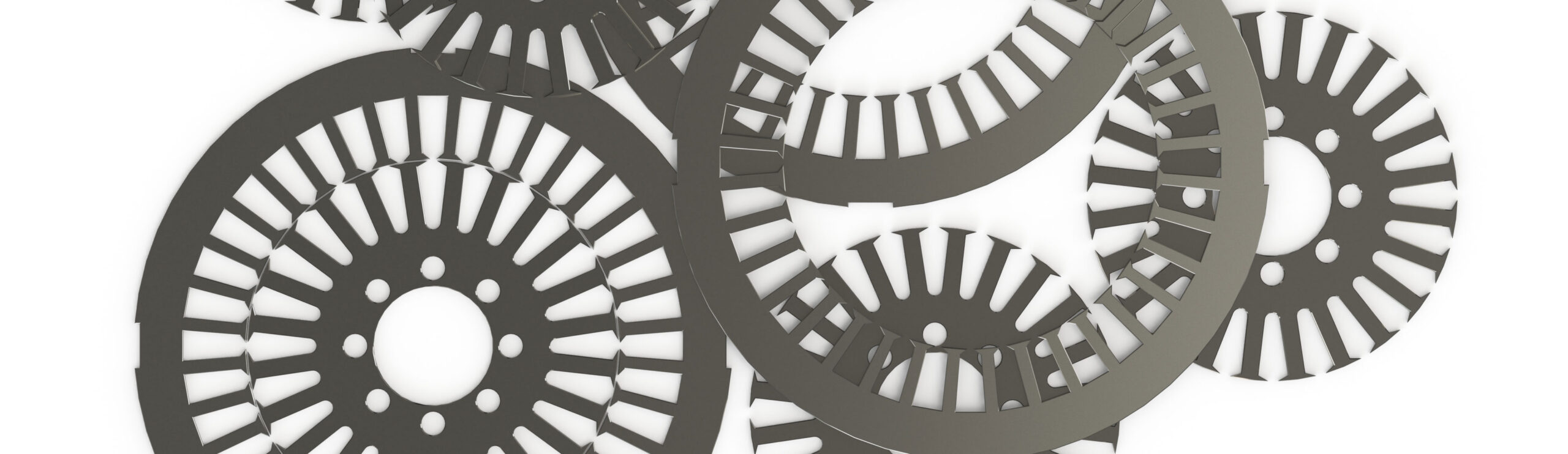

What is "Electrical Steel" and why is it used in Motor Designs?

Ian Matthews Golledge, Technical Manager, explains ...

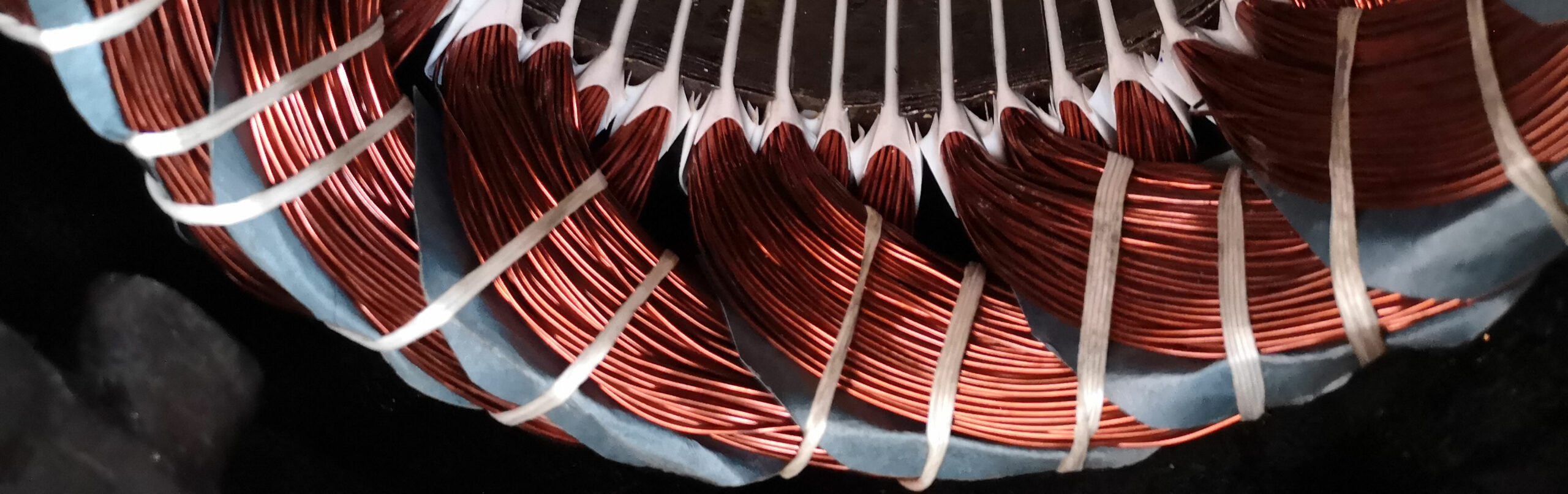

Electrical steel, also known as silicon steel or transformer steel, is a specialized type of steel alloy that is designed for use in electrical applications, particularly in the construction of electrical transformers, motors, and generators. It is called "electrical steel" because of its unique electrical and magnetic properties that make it ideal for these applications

Here are some key characteristics of electrical steel and why it is used in motor designs:

- Low Core Losses: Electrical steel is specifically formulated to have low core losses, which means it exhibits minimal energy loss due to hysteresis and eddy current losses when subjected to alternating magnetic fields. This property makes it highly efficient in applications where magnetic fields are constantly changing, such as in electric motors.

- High Magnetic Permeability: Electrical steel has a high magnetic permeability, which means it can easily conduct magnetic flux. This property allows it to efficiently transfer magnetic energy between the stator and rotor in electric motors, improving their overall performance and efficiency.

- Reduced Eddy Currents: The alloy composition and grain orientation in electrical steel are designed to minimize eddy currents, which are induced currents that circulate within the material in response to changing magnetic fields. Reduced eddy currents help to further lower energy losses and heat generation in electrical machines like motors

- High Resistivity: Electrical steel typically has a higher resistivity than regular steel. This property helps limit the flow of eddy currents and reduces the associated energy losses.

- Laminated Core Structure: Electrical steel sheets are typically laminated to further reduce eddy current losses. These sheets are coated with an insulating material, such as varnish or oxide, and then stacked together to form the core of the motor. This construction minimizes electrical conductivity between individual laminations, further improving the motor's efficiency

- Consistent Magnetic Properties: Electrical steel is manufactured with strict quality control to ensure consistent magnetic properties across the material. This uniformity is crucial for maintaining motor efficiency and performance.

- Minimal Magnetostriction: Magnetostriction is the phenomenon where a material changes shape under the influence of a magnetic field. Electrical steel is engineered to have minimal magnetostriction, reducing the risk of mechanical vibrations and noise in motors and transformers.

In summary, electrical steel is used in motor designs primarily because of its unique magnetic and electrical properties, which contribute to higher motor efficiency, reduced energy losses, and improved performance. These characteristics make electrical steel an essential material for various electrical machines, including electric motors, generators, and transformers

Want to find out more?

Get in touch